-

Exploring the Benefits and Applications of Butt Weld Elbows in Construction

Date:

19 Jul,2025

Butt weld elbows are critical components in piping systems, playing a vital role in ensuring fluid flow continuity and system integrity. When discussing these fittings, it's essential to understand their design, manufacturing processes, and the advantages they provide in various applications, particularly in construction and decorative materials. **Understanding Butt Weld Elbows** Butt weld elbow

Butt weld elbows are critical components in piping systems, playing a vital role in ensuring fluid flow continuity and system integrity. When discussing these fittings, it's essential to understand their design, manufacturing processes, and the advantages they provide in various applications, particularly in construction and decorative materials.

**Understanding Butt Weld Elbows**

Butt weld elbows are pipe fittings designed to connect two sections of pipe at an angle, typically either 90 or 45 degrees. They are manufactured by welding the elbow directly to the pipes, creating a smooth, continuous flow path that minimizes turbulence and pressure loss. This design is particularly advantageous in systems where efficient fluid transport is required.

**Advantages of Butt Weld Elbows**

1. **Strength and Durability**: The welding process creates a robust joint that can withstand high pressures and temperatures, making butt weld elbows ideal for demanding environments. This reliability reduces the likelihood of leaks, which can lead to costly repairs and system failures.

2. **Reduced Turbulence**: The seamless transition offered by butt weld elbows helps to reduce turbulence in the flow of liquids or gases. This feature is critical in maintaining system efficiency, particularly in applications involving high flow rates.

3. **Versatility in Applications**: Butt weld elbows are used across various industries, including oil and gas, water treatment, and construction. Their adaptability makes them suitable for both industrial and decorative piping systems, allowing for creative design solutions while maintaining functionality.

4. **Ease of Installation**: While the initial installation of butt weld elbows may require skilled labor and specialized tools, the resulting weld joint is often easier to maintain than threaded or flanged fittings. This can lead to lower long-term maintenance costs.

**Technical Considerations**

When selecting butt weld elbows for a project, it’s important to consider factors such as material compatibility, pressure ratings, and the specific application environment. Common materials include carbon steel, stainless steel, and alloy materials, each providing unique benefits depending on the operational conditions.

Furthermore, proper welding techniques are crucial for achieving the best performance from butt weld elbows. Adhering to industry standards and utilizing skilled welders can ensure the longevity and reliability of the piping system.

In summary, butt weld elbows are indispensable components in modern construction and piping systems. Their ability to provide strength, durability, and efficiency makes them a preferred choice for many applications. Understanding their benefits and technical requirements is essential for professionals aiming to optimize their projects and ensure system integrity.Related News

20 Jul,2025

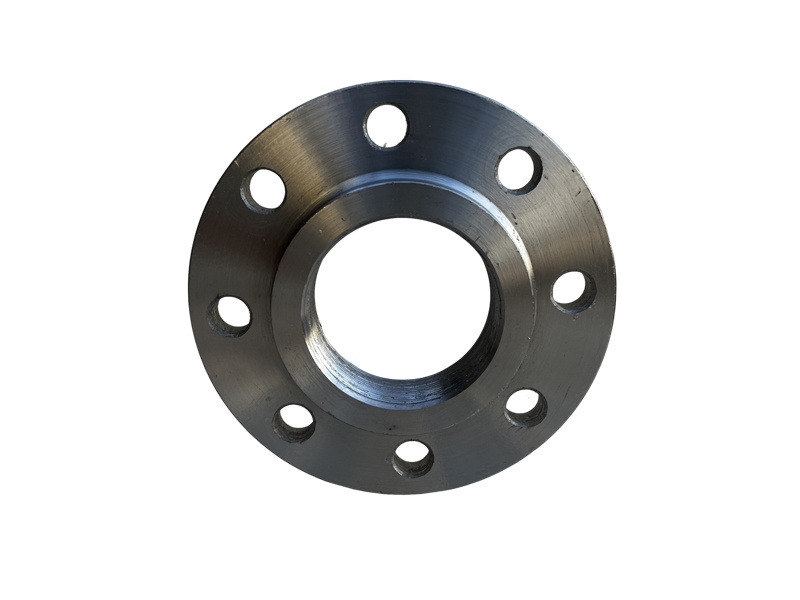

Lap Joint Flanges: The Ideal Solution for Easy Maintenance in Construction and Decorative Materials

Understanding Lap Joint Flanges: The Ultimate Guide for Easy Maintenance Lap joint flanges have become increasingly popular in various industries due to their unique design and functionality. They offer a simpler, cost-effective solution for pipe connections that require easy accessibility and maintenance. This article delves into the specifics of lap joint flanges, their benefits, applications, a

19 Jul,2025

Exploring the Benefits and Applications of Butt Weld Elbows in Construction

Butt weld elbows are critical components in piping systems, playing a vital role in ensuring fluid flow continuity and system integrity. When discussing these fittings, it's essential to understand their design, manufacturing processes, and the advantages they provide in various applications, particularly in construction and decorative materials. **Understanding Butt Weld Elbows** Butt weld elbow

18 Jul,2025

How to Properly Maintain Concentric Reducer Fittings for Longevity

How to Properly Maintain Concentric Reducer Fittings for Longevity Table of Contents 1. Introduction to Concentric Reducer Fittings 2. Understanding Concentric Reducers: What You Need to Know 3. Importance of Maintaining Concentric Reducer Fittings 4. Common Issues with Concentric Reducer Fittings 5. Essential Maintenance Tips for Longevity 6. How to Properly Inspect Conce

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message