-

The Environmental Impact of DIN Weld Neck Flanges PN40 Production: A Comprehensive Analysis

Date:

12 Jun,2025

The Environmental Impact of DIN Weld Neck Flanges PN40 Production In the ever-evolving landscape of industrial production, the focus on sustainability is becoming increasingly critical. One key component in various piping systems is the DIN Weld Neck Flange PN40, widely used in industries ranging from oil and gas to chemical processing. Understanding the environmental impact of producing these fla

The Environmental Impact of DIN Weld Neck Flanges PN40 Production

In the ever-evolving landscape of industrial production, the focus on sustainability is becoming increasingly critical. One key component in various piping systems is the DIN Weld Neck Flange PN40, widely used in industries ranging from oil and gas to chemical processing. Understanding the environmental impact of producing these flanges not only enhances our awareness but also informs better practices for the future. This article discusses the entire lifecycle of DIN Weld Neck Flanges PN40, from raw material extraction to manufacturing, usage, and end-of-life considerations.

Table of Contents

- Introduction to DIN Weld Neck Flanges PN40

- The Manufacturing Process of DIN Weld Neck Flanges

- Raw Materials and Their Environmental Impact

- Energy Consumption in Flange Production

- Waste Management Practices in Flange Manufacturing

- Implementing Sustainable Practices

- Case Studies of Sustainable Flange Production

- Future Implications for the Construction Materials Industry

- Frequently Asked Questions

- Conclusion

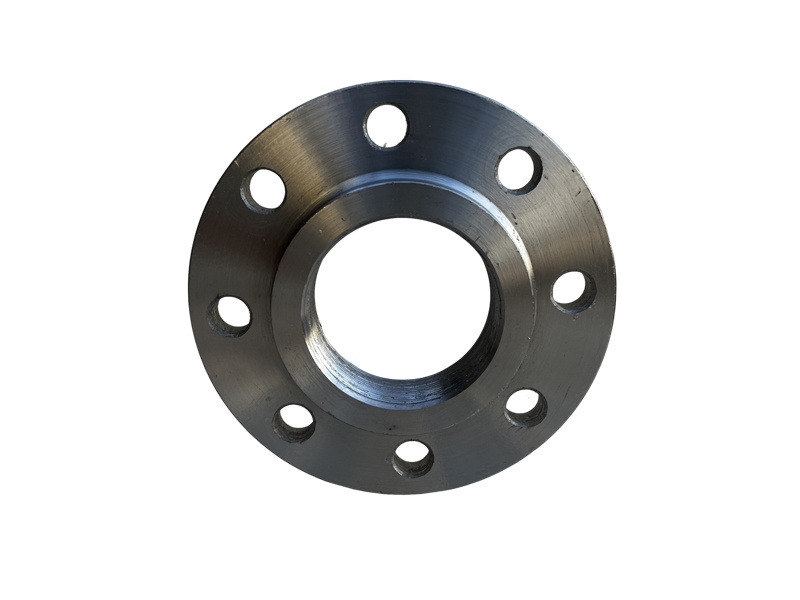

Introduction to DIN Weld Neck Flanges PN40

DIN Weld Neck Flanges PN40 are essential components in piping systems that require high-pressure handling capabilities. These flanges are designed to be welded to a pipe, creating a robust connection capable of withstanding significant stress and environmental conditions. However, the production of these flanges poses various environmental challenges. Understanding these challenges is crucial for manufacturers, policymakers, and consumers alike, as it helps pave the way for more sustainable practices within the industry.

The Manufacturing Process of DIN Weld Neck Flanges

The manufacturing of DIN Weld Neck Flanges involves several intricate steps, each contributing to the overall environmental impact. The production process typically includes:

1. Material Selection

The first step in manufacturing a DIN Weld Neck Flange is selecting appropriate materials, predominantly metals like carbon steel, stainless steel, and alloy steel. Each material's environmental impact varies based on its source and production method.

2. Forging and Shaping

Once the raw materials are selected, the next phase involves forging or shaping the flange. This process often requires significant energy, especially when using high-temperature techniques to mold the materials into the desired shape.

3. Machining

The machined process refines the flange dimensions and surfaces, making them ready for installation. This step generates waste materials and can contribute to pollution if not managed correctly.

4. Surface Treatment

Surface treatments, such as galvanization or coating, are applied to enhance durability and resistance to corrosion. While these treatments are crucial for performance, some chemicals used can have adverse environmental effects.

Raw Materials and Their Environmental Impact

The choice of raw materials is one of the most critical factors influencing the environmental footprint of DIN Weld Neck Flanges PN40 production. Let's explore the key materials used and their respective impacts:

1. Carbon Steel

Carbon steel is a common choice due to its strength and cost-effectiveness. However, its production involves significant carbon emissions, particularly during mining and processing.

2. Stainless Steel

Stainless steel, while more environmentally friendly due to its recyclability, often requires energy-intensive production methods, particularly in extracting nickel and chromium.

3. Alloy Steel

Alloy steel contains additional elements that enhance specific properties. Its production can lead to increased environmental impacts, especially if not sourced responsibly.

Energy Consumption in Flange Production

The energy required to produce DIN Weld Neck Flanges PN40 is substantial. Each phase of production, from material extraction to machining and finishing, requires electricity or fuel, leading to a considerable carbon footprint. Strategies to reduce energy consumption include:

1. Implementing Energy-Efficient Processes

Utilizing modern, energy-efficient machinery can significantly reduce energy consumption during production. Investing in technology that optimizes manufacturing processes contributes to lower emissions.

2. Using Renewable Energy Sources

Manufacturers can reduce their environmental impact by sourcing energy from renewable sources, such as solar or wind power. This shift not only decreases reliance on fossil fuels but also enhances the company’s sustainability profile.

Waste Management Practices in Flange Manufacturing

Proper waste management is crucial in minimizing the environmental impact of DIN Weld Neck Flange production. Effective strategies include:

1. Recycling Metal Waste

Recycling scrap metal generated during the manufacturing process not only conserves resources but also reduces the necessity for raw material extraction, thereby lowering environmental impacts.

2. Minimizing Chemical Waste

Ensuring that chemical waste from surface treatments is disposed of responsibly is vital. Manufacturers should adopt practices that limit chemical usage and promote the use of less harmful substances.

Implementing Sustainable Practices

To address the environmental impacts associated with DIN Weld Neck Flanges PN40 production, manufacturers can adopt various sustainable practices:

1. Eco-Friendly Materials

Opting for eco-friendly materials, such as recycled metals or alloys with lower environmental impacts, can significantly reduce a flange's overall carbon footprint.

2. Lifecycle Assessments

Conducting comprehensive lifecycle assessments helps identify areas for improvement in the production process. These assessments allow manufacturers to understand the environmental impacts from raw material extraction through to end-of-life disposal.

3. Certification and Standards

Adhering to international environmental standards, such as ISO 14001, can guide manufacturers in implementing effective environmental management systems that minimize their ecological footprint.

Case Studies of Sustainable Flange Production

Examining organizations that have successfully implemented sustainable practices can provide insights and inspiration for others in the industry. Consider the following examples:

1. Green Flange Manufacturing

A company specializing in DIN Weld Neck Flanges has transitioned to renewable energy sources, significantly reducing their carbon emissions. They focus on recycling materials and minimizing waste, setting a benchmark for sustainability in flange production.

2. Advanced Material Innovation

Another firm has developed a process utilizing thinner materials without sacrificing strength, which not only conserves resources but also reduces energy consumption during production.

Future Implications for the Construction Materials Industry

The future of DIN Weld Neck Flanges PN40 and their production will likely be shaped by ongoing advancements in technology, regulatory pressures, and consumer demand for sustainability. Areas to watch include:

1. Increased Regulation

As environmental concerns continue to mount, we can anticipate stricter regulations affecting the manufacturing processes and materials used in flange production. Companies that adapt proactively will likely thrive.

2. Technological Advancements

Innovations in manufacturing technologies could lead to more efficient processes, lower energy consumption, and enhanced material properties, further reducing the environmental impact of DIN Weld Neck Flanges.

3. Market Demand for Sustainable Products

As consumers and industries increasingly prioritize sustainability, manufacturers will need to respond by integrating eco-friendly practices and developing products that align with green standards.

Frequently Asked Questions

1. What are DIN Weld Neck Flanges PN40?

DIN Weld Neck Flanges PN40 are flanges designed for high-pressure applications, characterized by their long neck that allows for a smooth transition from the flange to the pipe.

2. How does the production of DIN Weld Neck Flanges affect the environment?

The production process involves significant energy consumption, raw material extraction, and waste generation, all of which have environmental impacts if not managed properly.

3. What steps can manufacturers take to reduce their environmental impact?

Manufacturers can adopt energy-efficient processes, utilize renewable energy, recycle materials, and ensure responsible waste management to minimize their ecological footprint.

4. Are there sustainable alternatives to traditional materials used in flange production?

Yes, manufacturers can explore using recycled metals or eco-friendly alloys that have a lower environmental impact compared to conventional materials.

5. Why is it important to consider the lifecycle of products in manufacturing?

Considering the lifecycle helps identify areas for improvement and allows manufacturers to implement practices that minimize environmental impacts throughout the product's life.

Conclusion

Understanding the environmental impact of DIN Weld Neck Flanges PN40 production is essential for fostering sustainability in the construction and decoration materials industry. Through responsible material sourcing, efficient manufacturing processes, and effective waste management practices, manufacturers can significantly reduce their ecological footprints. As the industry continues to evolve, embracing sustainable practices will not only benefit the environment but also enhance overall business resilience and consumer trust. With a collective effort towards sustainability, the future of DIN Weld Neck Flanges and the industries that rely on them can be more environmentally responsible and innovative.

Related News

13 Jun,2025

Understanding DIN Weld Neck Flanges PN40: Essential Insights for Your Projects

DIN weld neck flanges PN40 are a crucial component in piping systems, primarily utilized in applications requiring high pressure and temperature resistance. Designed according to the German Institute for Standardization (DIN), these flanges ensure compatibility and robustness in various industrial settings. ### Key Features of DIN Weld Neck Flanges PN40 1. **Design and Construction**: The weld nec

12 Jun,2025

The Environmental Impact of DIN Weld Neck Flanges PN40 Production: A Comprehensive Analysis

The Environmental Impact of DIN Weld Neck Flanges PN40 Production In the ever-evolving landscape of industrial production, the focus on sustainability is becoming increasingly critical. One key component in various piping systems is the DIN Weld Neck Flange PN40, widely used in industries ranging from oil and gas to chemical processing. Understanding the environmental impact of producing these fla

11 Jun,2025

Understanding BS4504 PN16 Weld Neck Flanges: Essential Knowledge for Professionals

--- In the realm of construction and decorative materials, particularly when it comes to piping systems, the BS4504 PN16 weld neck flange plays a critical role. Understanding what this component is, how it functions, and its applications can significantly benefit professionals in the industry. A weld neck flange is a type of flange that is designed to be welded to the pipe. The primary characteris

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message