-

Understanding the Importance of JIS 20K Weld Neck Flanges in Construction

Date:

20 Jun,2025

Understanding the Importance of JIS 20K Weld Neck Flanges in Construction Table of Contents 1. Introduction to JIS 20K Weld Neck Flanges 2. Key Design Features of JIS 20K Weld Neck Flanges 3. Material Options for Weld Neck Flanges 4. Common Applications of JIS 20K Weld Neck Flanges in Construction 5. Advantages of Using JIS 20K Weld Neck Flanges 6. Best Practices for Installing JIS 20

Understanding the Importance of JIS 20K Weld Neck Flanges in Construction

Table of Contents

- 1. Introduction to JIS 20K Weld Neck Flanges

- 2. Key Design Features of JIS 20K Weld Neck Flanges

- 3. Material Options for Weld Neck Flanges

- 4. Common Applications of JIS 20K Weld Neck Flanges in Construction

- 5. Advantages of Using JIS 20K Weld Neck Flanges

- 6. Best Practices for Installing JIS 20K Weld Neck Flanges

- 7. Maintenance Tips for Longevity

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to JIS 20K Weld Neck Flanges

In the world of construction and piping systems, the integrity of connections plays a pivotal role in ensuring safety and efficiency. Among the essential components used to create these connections are JIS 20K weld neck flanges. These flanges are designed to provide a robust and reliable interface between pipes, facilitating seamless fluid transfer while withstanding high pressure and temperature conditions. In this article, we will explore the significance of JIS 20K weld neck flanges, examining their design features, applications, and the many advantages they offer in construction projects.

2. Key Design Features of JIS 20K Weld Neck Flanges

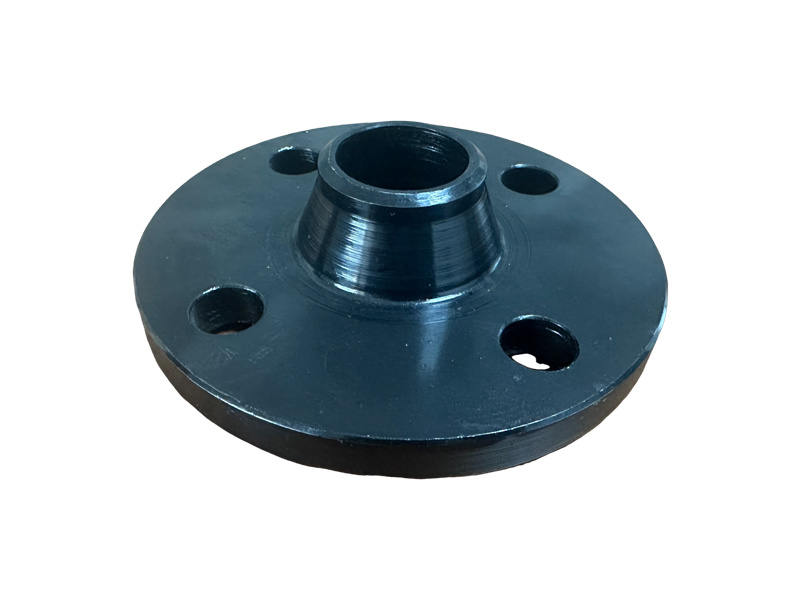

Weld neck flanges are readily distinguishable by their unique design, which includes a long tapered neck. This design facilitates a smooth transition between the flange and pipe, reducing stress concentrations that can lead to failures. Key design features include:

2.1 Tapered Neck for Enhanced Strength

The tapered neck of a JIS 20K weld neck flange contributes to its ability to handle high-pressure environments. This neck can accommodate various pipe sizes and thicknesses, allowing for versatility in construction applications.

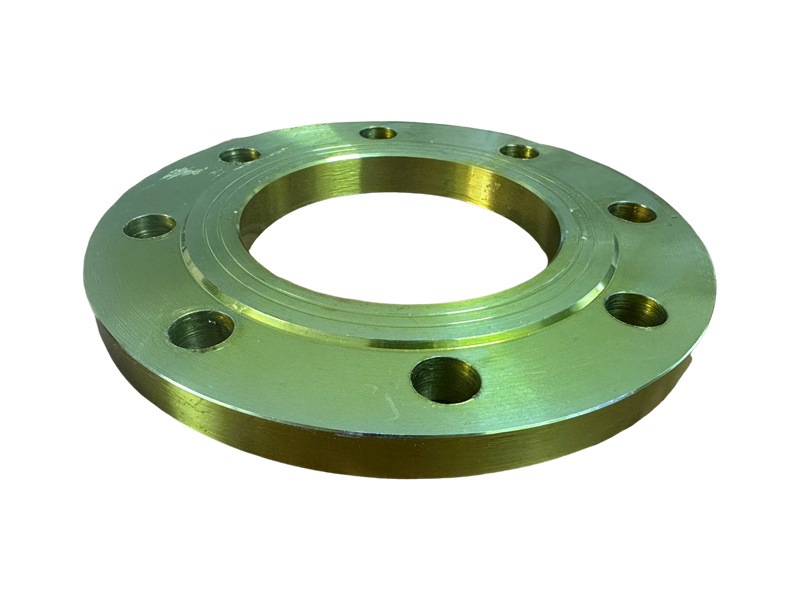

2.2 Face Types

JIS 20K weld neck flanges come in several face types, including raised face, flat face, and ring type joint. Each type serves specific purposes, depending on the application requirements and the materials used.

2.3 Bolt Hole Pattern

The bolt hole pattern of these flanges is designed to ensure a secure fit with corresponding pipes. The arrangement and size of the holes are critical in maintaining the integrity of the connection.

3. Material Options for Weld Neck Flanges

The materials used in the fabrication of JIS 20K weld neck flanges are crucial for their performance and longevity. Common materials include:

3.1 Carbon Steel

Carbon steel is widely used due to its excellent strength and durability. It is ideal for applications involving moderate pressure and temperature.

3.2 Stainless Steel

Stainless steel versions offer corrosion resistance, making them suitable for environments that involve exposure to moisture or chemicals. This material is often preferred in industries such as petrochemical and food processing.

3.3 Alloy Steel

Alloy steel flanges are designed to withstand extreme temperatures and pressures, making them essential in high-stress applications, such as power generation.

4. Common Applications of JIS 20K Weld Neck Flanges in Construction

JIS 20K weld neck flanges find extensive use in various applications across the construction industry. Some notable applications include:

4.1 Piping Systems

In industrial piping systems, JIS 20K weld neck flanges are used to connect pipes, valves, and other equipment, ensuring a leak-proof joint that can withstand high pressures.

4.2 Oil and Gas Industry

The oil and gas sector relies heavily on weld neck flanges for connecting pipelines that transport crude oil, natural gas, and other critical resources.

4.3 Water Treatment Facilities

Water treatment facilities utilize JIS 20K weld neck flanges for their durability and reliability in environments that require high levels of sanitation and pressure control.

5. Advantages of Using JIS 20K Weld Neck Flanges

The use of JIS 20K weld neck flanges offers several advantages that make them a preferred choice for construction projects:

5.1 Enhanced Structural Integrity

Weld neck flanges provide a robust connection that minimizes the risk of leaks and failures, ensuring the reliability of the entire piping system.

5.2 Ease of Installation

The design of JIS 20K weld neck flanges allows for straightforward installation procedures, which can reduce labor costs and improve project timelines.

5.3 Versatility

These flanges can be used across various industries and in a wide range of applications, making them a versatile choice for construction professionals.

5.4 Resistance to Corrosion

When crafted from stainless steel or alloy materials, JIS 20K weld neck flanges resist corrosion, contributing to the longevity of the installation.

6. Best Practices for Installing JIS 20K Weld Neck Flanges

Proper installation of JIS 20K weld neck flanges is crucial for ensuring their effectiveness in construction applications. Here are best practices to follow:

6.1 Surface Preparation

Before installation, both the flange and pipe surfaces must be cleaned and prepared to ensure a secure weld. Removing any contaminants is vital for achieving a strong bond.

6.2 Alignment

Proper alignment during installation ensures that the flange fits correctly with the pipe. Misalignment can lead to stress and eventual failure.

6.3 Welding Techniques

Utilizing the correct welding techniques, such as TIG or MIG welding, can greatly affect the quality of the joint. Skilled welders should be employed to ensure high-quality installation.

6.4 Inspection

After installation, inspecting the welds and flange connections is critical. Regular inspections can identify potential issues before they escalate into serious problems.

7. Maintenance Tips for Longevity

To maximize the lifespan of JIS 20K weld neck flanges, implementing a maintenance routine is essential. Key maintenance tips include:

7.1 Regular Inspections

Conducting frequent inspections of the connections can help detect any signs of wear or damage, allowing for timely repairs.

7.2 Cleaning

Keeping flanges clean from debris and corrosive substances will help maintain their integrity and performance.

7.3 Monitoring Pressure Levels

Regularly checking pressure levels in the piping system can prevent undue stress on flanges and ensure they operate within safe limits.

8. Conclusion

Understanding the importance of JIS 20K weld neck flanges in construction is crucial for industry professionals. Their unique design, material versatility, and strength make them an indispensable component in various applications. By adhering to best practices for installation and maintenance, construction teams can enhance the durability and reliability of their piping systems, ultimately leading to safer and more efficient operation. As we forge ahead in the construction industry, the significance of high-quality flanges like the JIS 20K cannot be overstated, underpinning the very infrastructure that supports our modern world.

9. Frequently Asked Questions

9.1 What is the primary purpose of a JIS 20K weld neck flange?

The primary purpose of a JIS 20K weld neck flange is to create a robust connection between pipes in high-pressure applications, ensuring a secure and leak-proof joint.

9.2 How do I determine the right material for my weld neck flanges?

The right material depends on the operating environment and specific application requirements, with options like carbon steel, stainless steel, or alloy steel available.

9.3 What are the common industries that utilize JIS 20K weld neck flanges?

Common industries include oil and gas, water treatment, chemical processing, and various manufacturing sectors.

9.4 How can I ensure the longevity of my weld neck flanges?

Regular inspections, proper cleaning, and adherence to installation protocols can significantly extend the lifespan of weld neck flanges.

9.5 Are JIS 20K weld neck flanges suitable for all types of piping systems?

While JIS 20K weld neck flanges are versatile, their suitability depends on the specific requirements of the piping system, including pressure, temperature, and material compatibility.Previous:

Related News

20 Jun,2025

Understanding the Importance of JIS 20K Weld Neck Flanges in Construction

Understanding the Importance of JIS 20K Weld Neck Flanges in Construction Table of Contents 1. Introduction to JIS 20K Weld Neck Flanges 2. Key Design Features of JIS 20K Weld Neck Flanges 3. Material Options for Weld Neck Flanges 4. Common Applications of JIS 20K Weld Neck Flanges in Construction 5. Advantages of Using JIS 20K Weld Neck Flanges 6. Best Practices for Installing JIS 20

18 Jun,2025

Why GOST Slip-On Flanges Are Essential for Your Next Project

Why GOST Slip-On Flanges Are Essential for Your Next Project Table of Contents Introduction to GOST Slip-On Flanges What Are GOST Slip-On Flanges? Benefits of Using GOST Slip-On Flanges Cost-Effectiveness Ease of Installation Versatility Across Applications Applications of GOST Slip-On Flanges in Various Industries Installa

17 Jun,2025

Understanding GOST Slip-On Flanges: A Key Component in Russian Construction

In the realm of construction and decorative materials, especially in the piping industry, GOST slip-on flanges play a vital role. Designed according to Russian standards, the GOST (Gosudarstvennyy Standart) specifications ensure that these flanges meet specific quality and performance criteria. The slip-on flange is a type of flange that is designed to slip over the pipe, providing a straightforwa

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message