-

Understanding the Benefits of Lap Joint Flanges in Construction: A Comprehensive Guide

Date:

26 Jun,2025

Understanding the Benefits of Lap Joint Flanges in Construction Table of Contents 1. Introduction to Lap Joint Flanges 2. What Are Lap Joint Flanges? 3. Advantages of Lap Joint Flanges 3.1 Enhanced Flexibility 3.2 Ease of Maintenance 3.3 Cost-Effectiveness 3.4 Compatibility with Various Pipes 4

Understanding the Benefits of Lap Joint Flanges in Construction

Table of Contents

- 1. Introduction to Lap Joint Flanges

- 2. What Are Lap Joint Flanges?

- 3. Advantages of Lap Joint Flanges

- 3.1 Enhanced Flexibility

- 3.2 Ease of Maintenance

- 3.3 Cost-Effectiveness

- 3.4 Compatibility with Various Pipes

- 4. Applications of Lap Joint Flanges

- 5. Installation Process

- 6. Comparing Lap Joint Flanges with Other Flanges

- 7. Frequently Asked Questions (FAQs)

- 8. Conclusion

1. Introduction to Lap Joint Flanges

In the construction industry, the choice of materials and components can significantly affect the overall success of a project. One essential component that often goes overlooked is the **lap joint flange**. This type of flange offers unique advantages that can improve the efficiency and effectiveness of a construction project. This article aims to provide a comprehensive understanding of lap joint flanges, exploring their benefits, applications, and installation methods.

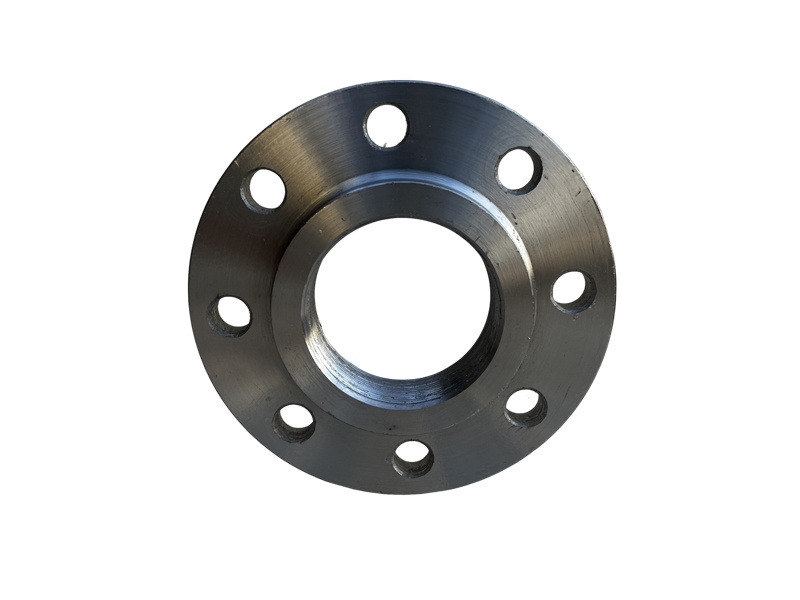

2. What Are Lap Joint Flanges?

Lap joint flanges consist of two primary components: a **stub end** and a **lap joint flange** itself. The stub end is welded to the pipe, while the lap joint flange is free to rotate around it. This design allows for easy alignment and disassembly. Lap joint flanges are typically made from various materials, including stainless steel and carbon steel, making them versatile for different environments.

3. Advantages of Lap Joint Flanges

When considering lap joint flanges, several advantages make them a preferred choice in various construction applications.

3.1 Enhanced Flexibility

One significant benefit of lap joint flanges is their **flexibility**. Because the flange can rotate around the stub end, it allows for easy alignment during installation. This characteristic is particularly advantageous in applications where pipe movement occurs, such as thermal expansion or vibrations.

3.2 Ease of Maintenance

Lap joint flanges simplify maintenance tasks. During routine inspections or repairs, the ability to easily disassemble the flange without disturbing the entire pipe system makes it a practical choice. This feature can lead to reduced downtime and lower service costs, contributing to overall project efficiency.

3.3 Cost-Effectiveness

From a financial perspective, lap joint flanges can be more cost-effective than other flange types. The installation process is straightforward, often requiring less labor and time. Additionally, the ability to reuse the stub end can lead to savings in material costs.

3.4 Compatibility with Various Pipes

These flanges are compatible with various pipe materials, including **PVC**, **carbon steel**, and **stainless steel**. This compatibility allows for greater flexibility in design and construction, making lap joint flanges a suitable option for diverse applications.

4. Applications of Lap Joint Flanges

Lap joint flanges find applications in various industries, including:

- **Chemical Processing:** Due to their corrosion resistance and ease of cleaning, lap joint flanges are ideal for chemical processing facilities.

- **Oil and Gas:** The ability to withstand adverse conditions makes them suitable for oil and gas applications.

- **Water Treatment:** Their functionality in environments with high moisture levels makes them a preferred choice in water treatment plants.

- **HVAC Systems:** In heating, ventilation, and air conditioning systems, lap joint flanges facilitate easy assembly and disassembly.

5. Installation Process

Installing lap joint flanges involves several steps to ensure a secure connection:

1. **Preparation of the Pipe and Stub End:** Clean the pipe ends and the stub end to ensure a tight fit. Any debris or rust can compromise the seal.

2. **Welding the Stub End:** Securely weld the stub end to the pipe. Ensure that the weld is even and strong to avoid leaks.

3. **Aligning the Flange:** Position the lap joint flange over the stub end. Its design allows for easy rotation, aiding in alignment.

4. **Securing the Flange:** Use bolts to secure the flange in place. Ensure that the bolts are tightened evenly to distribute pressure uniformly.

6. Comparing Lap Joint Flanges with Other Flanges

Understanding how lap joint flanges compare to other types, such as **slip-on flanges** and **weld neck flanges**, is vital in selecting the right flange for your project.

- **Slip-On Flanges:** These are easy to install but do not provide the same level of flexibility as lap joint flanges. They are more susceptible to leaks if not installed correctly.

- **Weld Neck Flanges:** Known for their strength, weld neck flanges are more challenging to install and may require more labor. They are also less flexible than lap joint flanges.

While each flange type has its advantages, lap joint flanges stand out for their ease of use, maintenance, and flexibility, making them ideal for projects requiring regular disassembly.

7. Frequently Asked Questions (FAQs)

Q1: What materials are lap joint flanges typically made from?

A1: Lap joint flanges are commonly made from **stainless steel**, **carbon steel**, and various alloys, making them suitable for different environments.

Q2: Can lap joint flanges be used in high-pressure applications?

A2: Yes, lap joint flanges can be designed for high-pressure applications, but it's essential to choose the right material and thickness to ensure safety.

Q3: What is the main advantage of using lap joint flanges over other types?

A3: The primary advantage is their **flexibility** and ease of disassembly, which simplifies maintenance and reduces downtime.

Q4: Are lap joint flanges suitable for corrosive environments?

A4: Yes, when made from corrosion-resistant materials like stainless steel, lap joint flanges can perform well in corrosive environments.

Q5: How do I ensure a proper seal with lap joint flanges?

A5: To ensure a proper seal, carefully prepare the surfaces, use the appropriate gasket material, and tighten the bolts evenly.

8. Conclusion

Lap joint flanges offer a range of benefits that make them an excellent choice for construction projects. Their **flexibility**, **ease of maintenance**, and **cost-effectiveness** set them apart from other flange types. Understanding their applications and installation processes is crucial for anyone in the construction industry. By selecting the right flange for your project, you can ensure a reliable and efficient construction process that meets your specific needs. Investing in quality lap joint flanges can lead to improved project outcomes, reduced costs, and enhanced maintenance capabilities, solidifying their status as a valuable component in modern construction.Related News

26 Jun,2025

Understanding the Benefits of Lap Joint Flanges in Construction: A Comprehensive Guide

Understanding the Benefits of Lap Joint Flanges in Construction Table of Contents 1. Introduction to Lap Joint Flanges 2. What Are Lap Joint Flanges? 3. Advantages of Lap Joint Flanges 3.1 Enhanced Flexibility 3.2 Ease of Maintenance 3.3 Cost-Effectiveness 3.4 Compatibility with Various Pipes 4

25 Jun,2025

The Essential Guide to Butt Weld Elbows in Construction and Decoration

Butt weld elbows are crucial components in piping systems used widely in various industries, including construction and decoration. These fittings allow for changes in direction within a pipeline, making them essential for efficient flow and structural integrity. When it comes to choosing the right fittings for your projects, understanding the practicalities of butt weld elbows can significantly a

24 Jun,2025

Common Mistakes to Avoid When Installing Concentric Reducer Fittings Table of Contents 1. Understanding Concentric Reducer Fittings 2. Importance of Proper Installation Techniques 3. Common Mistakes to Avoid 3.1 Ignoring Proper Measurements 3.2 Failing to Use Appropriate Tools 3.3 Neglecting Surface Preparation 3.4 Over-tightening Connections 3.5 Skipping Quality Checks 4. Best Practices for Insta

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message