-

Why Choose Lap Joint Flanges for Your Piping Needs? A Comprehensive Guide

Date:

04 Jul,2025

Why Choose Lap Joint Flanges for Your Piping Needs? When selecting components for your piping systems, the choice of flanges plays a crucial role in ensuring durability, efficiency, and safety. Among the various types of flanges available, lap joint flanges have gained popularity due to their unique design and practical advantages. In this comprehensive guide, we will explore the reasons to choose

Why Choose Lap Joint Flanges for Your Piping Needs?

When selecting components for your piping systems, the choice of flanges plays a crucial role in ensuring durability, efficiency, and safety. Among the various types of flanges available, lap joint flanges have gained popularity due to their unique design and practical advantages. In this comprehensive guide, we will explore the reasons to choose lap joint flanges, their applications, benefits, and technical specifications.

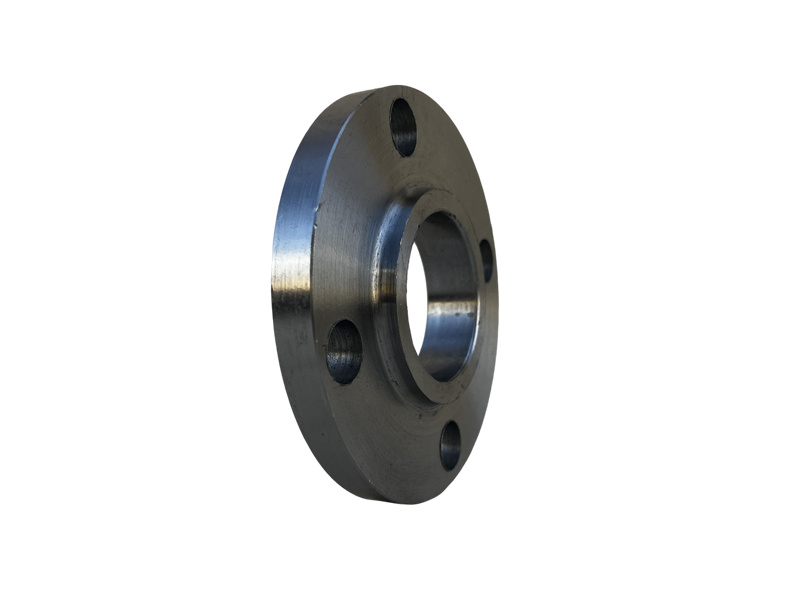

Understanding Lap Joint Flanges

Lap joint flanges are characterized by their unique construction, which consists of two main parts: the flange itself and a loose backing ring. This design allows for greater flexibility and ease of assembly, making them ideal for various piping applications.

The Design and Structure of Lap Joint Flanges

The design of lap joint flanges consists of a flat or raised face that is connected to the pipe. The backing ring, which is separate from the flange, fits over the pipe and allows for alignment and adjustment during installation. This feature is particularly beneficial when dealing with misaligned or irregular surfaces.

Key Features of Lap Joint Flanges

1. **Ease of Installation**: Lap joint flanges are easier to install than other types of flanges, as they do not require precise alignment during assembly.

2. **Versatility**: They can be used with various pipe materials, including carbon steel, stainless steel, and more.

3. **Reduced Corrosion Risk**: The design minimizes crevices that can trap moisture, reducing the risk of corrosion.

4. **Flexible Alignment**: The loose backing ring allows for greater flexibility in aligning the pipes.

Advantages of Using Lap Joint Flanges

Choosing lap joint flanges for your piping needs comes with a host of benefits. Here are some key advantages that make them an ideal choice for many applications.

1. Cost-Effectiveness

Lap joint flanges are typically more cost-effective than other flange types. Their design allows for easier installation, which can save on labor costs. Moreover, they are compatible with various pipe materials, reducing the need for specialized fittings.

2. Simplified Maintenance

Maintenance becomes straightforward with lap joint flanges. The design allows for easy disassembly, making it convenient to access the piping system for repairs or inspections. This ease of maintenance can lead to lower operational costs over time.

3. Enhanced Flexibility

Lap joint flanges offer enhanced flexibility when it comes to installation. They can accommodate slight misalignments in the piping system, making them suitable for dynamic applications where movement is expected. This flexibility is especially beneficial in industrial settings.

4. Improved Sealing Performance

The ability to achieve a tight seal is paramount in piping systems. Lap joint flanges provide excellent sealing performance, thanks to the compression of the gasket when the flange is bolted. This reduces the likelihood of leaks, ensuring the integrity of the system.

Applications of Lap Joint Flanges

Lap joint flanges find utility across various industries due to their unique advantages. Here are some common applications where lap joint flanges are the preferred choice.

1. Chemical Processing Plants

In chemical processing plants, where the integrity of piping systems is crucial, lap joint flanges offer the necessary flexibility and sealing performance to handle various chemicals safely.

2. Oil and Gas Industry

The oil and gas industry often requires robust piping solutions capable of withstanding harsh conditions. Lap joint flanges provide the durability and adaptability needed for exploration and extraction processes.

3. Water Treatment Facilities

Water treatment facilities benefit from the corrosion-resistant properties of lap joint flanges, ensuring the longevity of piping systems that handle water and wastewater.

4. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, lap joint flanges are used to connect ductwork and piping. Their ease of maintenance makes them ideal for systems requiring regular inspections and adjustments.

Technical Specifications of Lap Joint Flanges

When selecting lap joint flanges, it is essential to consider their technical specifications to ensure compatibility with your piping systems. Here are some key specifications to keep in mind.

1. Material Options

Lap joint flanges are available in various materials, including carbon steel, stainless steel, and alloyed materials. The choice of material depends on the application's specific requirements, such as temperature, pressure, and corrosion resistance.

2. Size Range

Lap joint flanges come in various sizes to accommodate different pipe diameters. It is crucial to select the appropriate size for your piping system to ensure a proper fit.

3. Pressure Ratings

Understanding the pressure ratings of lap joint flanges is vital for safety and efficiency. Common pressure classes include 150, 300, 600, and higher ratings, depending on the application.

4. Surface Finish

The surface finish of lap joint flanges can impact their performance. A smooth finish can enhance sealing capabilities, while a rough finish may provide better grip during assembly.

Installation Best Practices for Lap Joint Flanges

Proper installation of lap joint flanges is essential to ensure their effectiveness. Here are some best practices to follow during the installation process.

1. Preparation of the Pipe Ends

Ensure that the pipe ends are clean and free of debris. Any imperfections can hinder the sealing capability of the flange.

2. Aligning the Flanges

Align the lap joint flange with the corresponding pipe. The loose backing ring should fit over the pipe, allowing for adjustments during installation.

3. Gasket Placement

Place a suitable gasket between the flange faces to enhance sealing. Ensure that the gasket is compatible with the fluids being transported.

4. Torque Specifications

Follow the manufacturer's torque specifications when tightening the bolts. Over-tightening can lead to flange deformation, while under-tightening may result in leaks.

Common Mistakes to Avoid When Using Lap Joint Flanges

While lap joint flanges offer numerous advantages, certain mistakes can compromise their effectiveness. Here are some common pitfalls to avoid.

1. Ignoring Compatibility

Always ensure that the lap joint flanges are compatible with the pipes and materials used in your system. Mismatched materials can lead to corrosion and failure.

2. Neglecting Maintenance

Regular maintenance is crucial for the longevity of lap joint flanges. Neglecting routine inspections can result in undetected leaks and costly repairs.

3. Improper Torque Application

Applying incorrect torque can damage the flange and compromise its sealing capability. Always reference manufacturer guidelines for proper torque specifications.

FAQs About Lap Joint Flanges

1. What are lap joint flanges made of?

Lap joint flanges are typically made from materials like carbon steel, stainless steel, and other alloys, depending on their intended application.

2. How do you install lap joint flanges?

Installation involves aligning the flange with the pipe, placing a gasket, and tightening bolts according to specified torque values.

3. Are lap joint flanges suitable for high-pressure applications?

Yes, lap joint flanges can be designed for high-pressure applications, but it is essential to select the appropriate pressure rating and material.

4. Can lap joint flanges be reused?

Lap joint flanges can typically be reused, provided they show no signs of damage or wear during inspection.

5. What is the difference between lap joint flanges and slip-on flanges?

Lap joint flanges feature a loose backing ring for flexibility, while slip-on flanges are welded directly to the pipe, offering a more rigid connection.

Conclusion

In conclusion, choosing lap joint flanges for your piping needs is a decision that can yield significant benefits in terms of flexibility, maintenance, and cost-effectiveness. Their unique design and versatility make them suitable for a wide range of applications, from chemical processing to HVAC systems. By understanding their advantages, applications, and installation best practices, you can ensure that your piping systems operate efficiently and reliably. Investing in lap joint flanges can ultimately lead to a more efficient, durable, and cost-effective piping solution.Related News

04 Jul,2025

Why Choose Lap Joint Flanges for Your Piping Needs? A Comprehensive Guide

Why Choose Lap Joint Flanges for Your Piping Needs? When selecting components for your piping systems, the choice of flanges plays a crucial role in ensuring durability, efficiency, and safety. Among the various types of flanges available, lap joint flanges have gained popularity due to their unique design and practical advantages. In this comprehensive guide, we will explore the reasons to choose

03 Jul,2025

Understanding Butt Weld Elbows: Essential Knowledge for Construction and Decoration Professionals

Butt weld elbows are a crucial element in piping systems, especially within the construction and decoration materials sector. These fittings are designed to connect two pipes at an angle, typically 45 or 90 degrees, promoting smooth fluid flow while minimizing turbulence. Understanding the characteristics and advantages of butt weld elbows can significantly impact project outcomes, making it essen

02 Jul,2025

The Impact of Concentric Reducer Fittings on Water Flow Dynamics: A Comprehensive Guide

The Impact of Concentric Reducer Fittings on Water Flow Dynamics Table of Contents 1. Introduction to Concentric Reducer Fittings 2. Understanding Water Flow Dynamics 2.1 The Fundamentals of Fluid Mechanics 2.2 The Role of Pipe Diameter in Flow Rate 3. Overview of Concentric Reducer Fittings 3.1 Design and Structure 3.2 Material Composition 4. Functionality of Concentric Reducer

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message