-

The Integral Function of BS4504 PN16 Weld Neck Flanges in Pipe Fittings

Date:

24 Jul,2025

The Integral Function of BS4504 PN16 Weld Neck Flanges in Pipe Fittings Table of Contents 1. Introduction to BS4504 PN16 Weld Neck Flanges 2. Understanding Different Types of Flanges 3. Overview of the BS4504 Standard 4. The Significance of PN16 Rating 5. Design and Construction of Weld Neck Flanges 6. Applications of BS4504 PN16 Weld Neck Flanges 7. Advantages of Usin

The Integral Function of BS4504 PN16 Weld Neck Flanges in Pipe Fittings

Table of Contents

- 1. Introduction to BS4504 PN16 Weld Neck Flanges

- 2. Understanding Different Types of Flanges

- 3. Overview of the BS4504 Standard

- 4. The Significance of PN16 Rating

- 5. Design and Construction of Weld Neck Flanges

- 6. Applications of BS4504 PN16 Weld Neck Flanges

- 7. Advantages of Using BS4504 PN16 Weld Neck Flanges

- 8. Installation Tips for Weld Neck Flanges

- 9. Maintenance and Care for Longevity

- 10. Conclusion

- 11. Frequently Asked Questions

1. Introduction to BS4504 PN16 Weld Neck Flanges

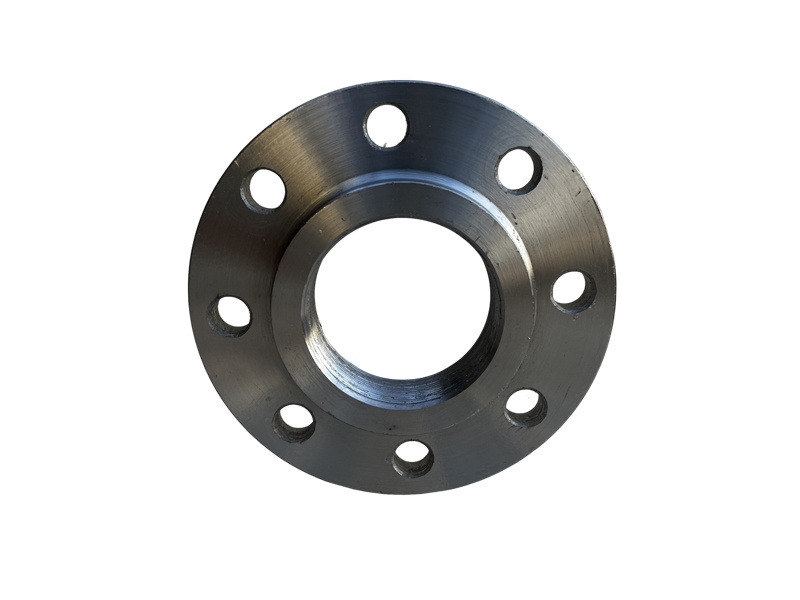

BS4504 PN16 weld neck flanges are crucial components in piping systems, particularly in various industrial applications. They connect pipes, valves, and other equipment securely, ensuring flow integrity and system reliability. Their unique design allows them to withstand high pressures and temperatures, making them ideal for demanding environments.

This article aims to provide a detailed understanding of BS4504 PN16 weld neck flanges, exploring their specifications, advantages, and best practices in installation and maintenance.

2. Understanding Different Types of Flanges

Flanges come in various types, each serving specific functions in pipe fittings. Understanding these types can help you choose the right flange for your project:

2.1. Slip-On Flanges

Slip-on flanges are easy to install and align. They fit over the pipe, making them ideal for low-pressure applications.

2.2. Blind Flanges

Used to seal the end of a pipe, blind flanges are essential for testing and inspection processes in a system.

2.3. Socket Weld Flanges

These flanges are welded to pipes, providing strong connections for high-pressure applications.

2.4. Weld Neck Flanges

Weld neck flanges, such as the BS4504 PN16, are designed for high-pressure environments. They are welded directly to the pipe, providing a robust joint and reducing stress concentrations.

3. Overview of the BS4504 Standard

The BS4504 standard is a British Standard that outlines the specifications and dimensions for flanges and their corresponding fittings. It ensures uniformity and safety in the manufacturing and usage of flanges and fittings across various industries. The standard classifies several flange types, including weld neck, slip-on, and blind flanges, and provides guidelines on materials, dimensions, and tolerances.

4. The Significance of PN16 Rating

The "PN" in PN16 refers to the nominal pressure rating of the flange. A PN16 rating indicates that the flange can handle a maximum pressure of 16 bar (approximately 232 psi) at a specific temperature. This rating is critical in selecting the right flange for applications that require precise pressure management. It ensures that the flange can withstand the operational demands of the system without risk of failure.

5. Design and Construction of Weld Neck Flanges

Weld neck flanges have a unique design characterized by a long neck that gradually transitions to the flange body. This design helps distribute stress evenly, reducing the likelihood of failure under high-pressure conditions.

5.1. Material Selection

Weld neck flanges can be manufactured from various materials, including carbon steel, stainless steel, and alloy steel. The choice of material depends on the application, temperature, and corrosion resistance requirements.

5.2. Dimensions and Specifications

The dimensions of BS4504 PN16 weld neck flanges are standardized, ensuring compatibility with various pipe sizes and fittings. Key dimensions include the flange diameter, bolt hole diameter, and the thickness of the flange.

6. Applications of BS4504 PN16 Weld Neck Flanges

BS4504 PN16 weld neck flanges are used in various industries, including:

6.1. Oil and Gas Industry

In the oil and gas sector, these flanges are used in pipelines for crude oil and natural gas transportation. Their ability to handle high pressures makes them ideal for this application.

6.2. Chemical Processing

Chemical plants often use BS4504 PN16 weld neck flanges for piping systems that transport corrosive materials. Their robust construction ensures safety and reliability.

6.3. Water Treatment Facilities

In water treatment plants, these flanges are employed in large-scale piping systems, ensuring effective flow control and pressure management.

6.4. Power Generation

The power generation industry utilizes weld neck flanges in steam and water pipelines, where high-pressure conditions are prevalent.

7. Advantages of Using BS4504 PN16 Weld Neck Flanges

Utilizing BS4504 PN16 weld neck flanges offers several advantages:

7.1. High Pressure Resistance

These flanges can withstand high pressures, making them suitable for demanding applications.

7.2. Stress Distribution

Their design allows for even stress distribution, reducing the likelihood of leaks or failures.

7.3. Versatile Applications

They can be utilized across various industries, providing flexibility in their use.

7.4. Enhanced Safety

The robust construction minimizes the risk of catastrophic failures, ensuring safe operation in critical systems.

8. Installation Tips for Weld Neck Flanges

Proper installation is crucial for the performance of BS4504 PN16 weld neck flanges. Here are some essential tips:

8.1. Ensure Proper Alignment

Misalignment can lead to stress concentrations and potential failure. Always check the alignment before installation.

8.2. Use Appropriate Welding Techniques

Employ proper welding techniques to ensure a strong joint. The weld area should be clean and free of contaminants.

8.3. Torque Specifications

Follow the manufacturer’s torque specifications for the bolts to ensure a secure connection without over-tightening.

9. Maintenance and Care for Longevity

Regular maintenance is essential for the longevity of BS4504 PN16 weld neck flanges.

9.1. Regular Inspections

Conduct regular inspections for signs of wear, corrosion, or leaks. Early detection can prevent major failures.

9.2. Cleaning

Keep flanges clean to prevent corrosion. Use appropriate cleaning agents that do not harm the flange material.

9.3. Re-tightening Bolts

Re-check torque on bolts periodically, as they may loosen over time due to vibration or thermal cycles.

10. Conclusion

BS4504 PN16 weld neck flanges play an indispensable role in the reliability and safety of piping systems across various industries. Their robust design, high-pressure resistance, and versatility make them a preferred choice for many applications. By understanding their specifications, applications, and best practices for installation and maintenance, you can ensure optimal performance in your piping systems.

11. Frequently Asked Questions

1. What materials are used for BS4504 PN16 weld neck flanges?

BS4504 PN16 weld neck flanges are typically made from carbon steel, stainless steel, and alloy steel, depending on the application requirements.

2. Are BS4504 PN16 flanges suitable for high-temperature applications?

Yes, these flanges are designed to withstand high pressures and temperatures, making them suitable for demanding environments.

3. How do I ensure proper installation of weld neck flanges?

Ensure proper alignment, use the correct welding techniques, and follow torque specifications for bolts during installation.

4. What industries commonly use BS4504 PN16 weld neck flanges?

These flanges are prevalent in the oil and gas, chemical processing, water treatment, and power generation industries.

5. How can I maintain my weld neck flanges for longevity?

Perform regular inspections, keep the flanges clean, and periodically check and re-tighten bolts to ensure longevity and safe operation.

By understanding the critical role of BS4504 PN16 weld neck flanges, industries can enhance their operational safety and efficiency, ensuring that systems operate smoothly under varying conditions.Related News

25 Jul,2025

Understanding DIN Weld Neck Flange PN40: A Key Component in Construction and Decoration

In the realm of construction and decorative materials, the DIN weld neck flange PN40 is a critical component that ensures robust connectivity and safety in piping systems. This type of flange is designed according to the German Institute for Standardization (DIN) standards and is categorized under pressure rating PN40, indicating its capability to handle high pressures. A weld neck flange is chara

24 Jul,2025

The Integral Function of BS4504 PN16 Weld Neck Flanges in Pipe Fittings

The Integral Function of BS4504 PN16 Weld Neck Flanges in Pipe Fittings Table of Contents 1. Introduction to BS4504 PN16 Weld Neck Flanges 2. Understanding Different Types of Flanges 3. Overview of the BS4504 Standard 4. The Significance of PN16 Rating 5. Design and Construction of Weld Neck Flanges 6. Applications of BS4504 PN16 Weld Neck Flanges 7. Advantages of Usin

23 Jul,2025

Understanding GOST 12820-80 Plate Flange: Key Insights for Construction and Decoration

GOST 12820-80 is a standard developed in the Soviet Union that outlines the specifications for plate flanges used in various piping systems. These flanges are particularly crucial in industries involving construction and decorative materials, where the integrity of piping systems must be maintained to ensure safety and functionality. Understanding the characteristics and applications of GOST 12820

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message