-

Understanding BS10 Table D Flanges: Essential Insights for Professionals

Date:

27 Jun,2025

In the construction and decorative materials industry, specifically within piping systems, understanding the specifications and applications of various fittings is crucial. One such important component is the BS10 Table D flange. Designed to meet specific international standards, the BS10 Table D flange is widely recognized for its reliability and efficiency in fluid transport systems. BS10 Table

In the construction and decorative materials industry, specifically within piping systems, understanding the specifications and applications of various fittings is crucial. One such important component is the BS10 Table D flange. Designed to meet specific international standards, the BS10 Table D flange is widely recognized for its reliability and efficiency in fluid transport systems.

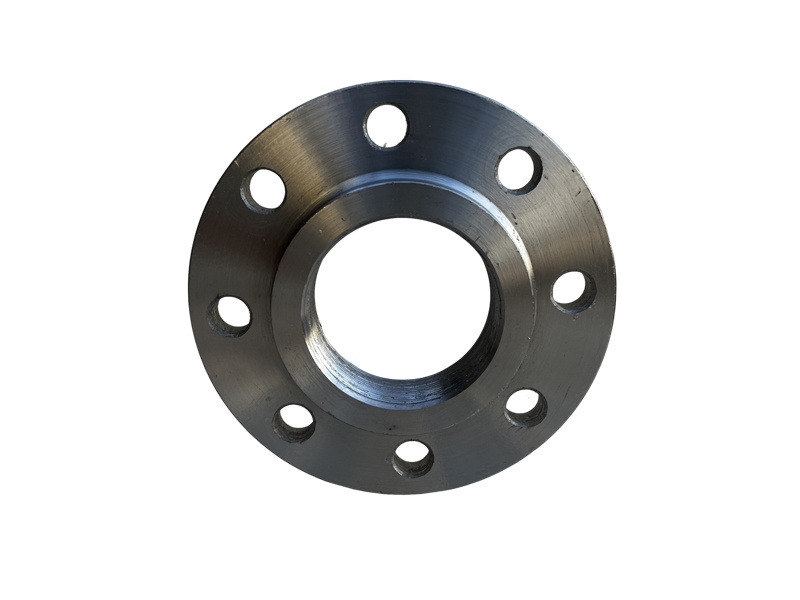

BS10 Table D flanges are categorized under British Standard 10, which outlines the dimensions, tolerances, and pressure ratings for flanges. This standardization ensures compatibility with a wide range of pipes and fittings, making it easier for engineers and contractors to design and implement effective piping solutions. The dimensions of Table D flanges are defined by the nominal size of the pipe, ensuring a snug fit that minimizes leakage and enhances the overall integrity of the piping system.

Typically, BS10 Table D flanges are made from materials such as carbon steel, stainless steel, and alloy steels. The choice of material can significantly impact the flange's performance, particularly in relation to temperature and pressure conditions. For instance, stainless steel flanges are often preferred in corrosive environments, while carbon steel flanges are commonly used in less demanding applications.

One of the key advantages of using BS10 Table D flanges is their versatility. They can be used in a variety of applications, including water supply systems, chemical transport, and HVAC systems. Their robust design allows them to handle high-pressure and high-temperature applications efficiently, making them suitable for both domestic and industrial uses.

When installing BS10 Table D flanges, it is important to consider the proper gasket selection and bolting techniques. The right gasket will ensure a tight seal between the flange faces, preventing leaks and maintaining system efficiency. Additionally, proper bolt tightening is crucial to achieving the desired pressure rating and preventing flange failure.

Maintenance is another critical aspect of using BS10 Table D flanges. Regular inspections should be carried out to check for signs of corrosion, wear, or damage. Prompt maintenance can help extend the lifespan of the flanges and overall piping system, ensuring long-term reliability.

In conclusion, BS10 Table D flanges play a vital role in the construction and decorative materials sector, particularly in piping systems. Understanding their specifications, material options, and best practices for installation and maintenance can greatly enhance the effectiveness of fluid transport systems. For professionals in the industry, staying informed about these flanges is essential for ensuring optimal performance and safety in their projects.Related News

27 Jun,2025

Understanding BS10 Table D Flanges: Essential Insights for Professionals

In the construction and decorative materials industry, specifically within piping systems, understanding the specifications and applications of various fittings is crucial. One such important component is the BS10 Table D flange. Designed to meet specific international standards, the BS10 Table D flange is widely recognized for its reliability and efficiency in fluid transport systems. BS10 Table

26 Jun,2025

Understanding the Benefits of Lap Joint Flanges in Construction: A Comprehensive Guide

Understanding the Benefits of Lap Joint Flanges in Construction Table of Contents 1. Introduction to Lap Joint Flanges 2. What Are Lap Joint Flanges? 3. Advantages of Lap Joint Flanges 3.1 Enhanced Flexibility 3.2 Ease of Maintenance 3.3 Cost-Effectiveness 3.4 Compatibility with Various Pipes 4

25 Jun,2025

The Essential Guide to Butt Weld Elbows in Construction and Decoration

Butt weld elbows are crucial components in piping systems used widely in various industries, including construction and decoration. These fittings allow for changes in direction within a pipeline, making them essential for efficient flow and structural integrity. When it comes to choosing the right fittings for your projects, understanding the practicalities of butt weld elbows can significantly a

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message