-

JIS B2220 10K Flange: Bridging Gaps in Pipeline Connections

Date:

06 Jul,2025

JIS B2220 10K Flange: Bridging Gaps in Pipeline Connections Pipeline systems are the backbone of various industries, facilitating the transportation of fluids and gases across vast distances. At the heart of these systems lie the components that ensure smooth and secure connections, among which the **JIS B2220 10K flange** stands out as a crucial element. In this article, we delve into the specifi

JIS B2220 10K Flange: Bridging Gaps in Pipeline Connections

Pipeline systems are the backbone of various industries, facilitating the transportation of fluids and gases across vast distances. At the heart of these systems lie the components that ensure smooth and secure connections, among which the **JIS B2220 10K flange** stands out as a crucial element. In this article, we delve into the specifics of the JIS B2220 10K flange, exploring its specifications, applications, benefits, and installation techniques to illuminate its significance in pipeline connections.

Table of Contents

- What is JIS B2220 10K Flange?

- Specifications of JIS B2220 10K Flange

- Applications of JIS B2220 10K Flange

- Benefits of Using JIS B2220 10K Flange

- Installation Techniques for JIS B2220 10K Flange

- Maintenance and Care for JIS B2220 10K Flange

- Common Issues and Solutions

- Frequently Asked Questions

What is JIS B2220 10K Flange?

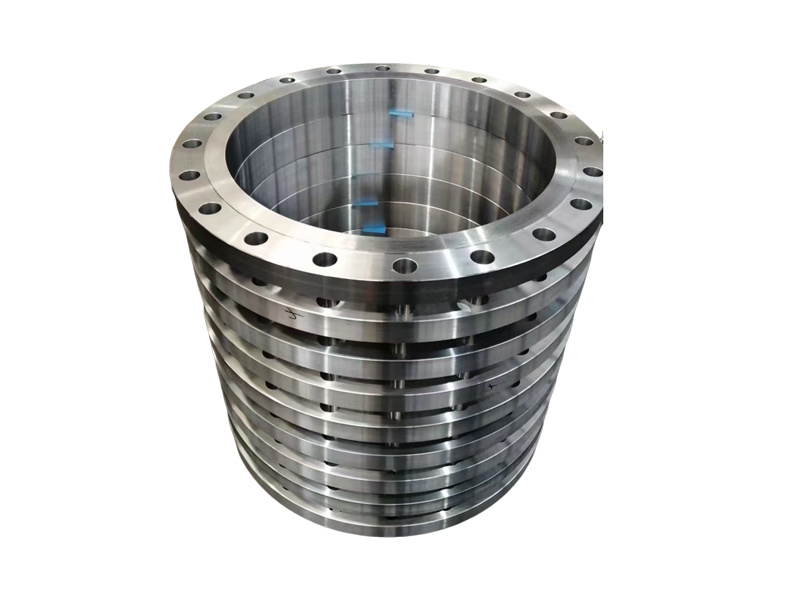

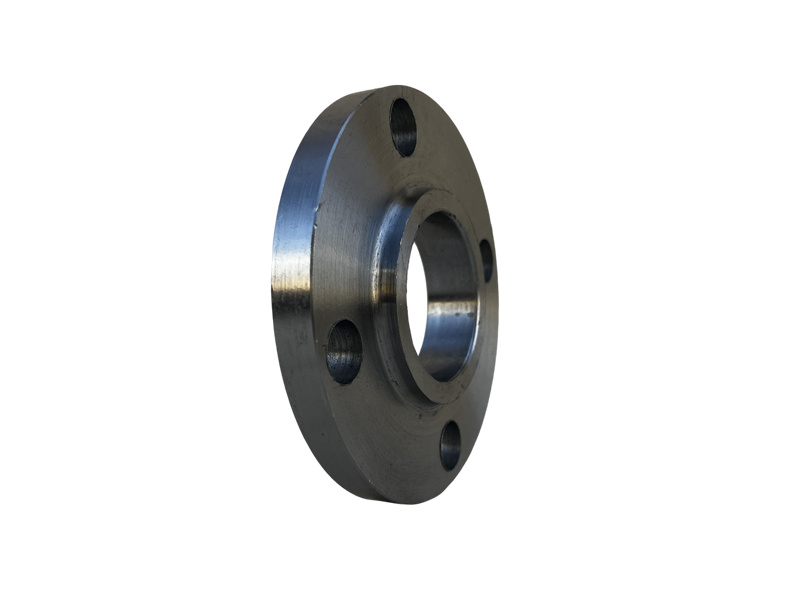

The **JIS B2220 10K flange** is a specific type of flange standardized by the Japanese Industrial Standards (JIS). It is designed for piping systems to connect two sections of a pipe or to connect a pipe to a valve, pump, or other equipment. The "10K" designation indicates that this flange can handle a maximum pressure of 10 kilograms per square centimeter, making it suitable for various fluid transport applications.

Characterized by its circular shape, the JIS B2220 10K flange typically features bolt holes arranged in a circular pattern, allowing for secure fastening. These flanges are available in various materials, including carbon steel, stainless steel, and alloy steel, which can be selected based on the specific requirements of the application.

Specifications of JIS B2220 10K Flange

Understanding the specifications of JIS B2220 10K flanges is paramount for ensuring their proper application and functionality. The key specifications include:

Dimensions

The dimensions of the JIS B2220 10K flange vary based on the nominal pipe size (NPS). Commonly used sizes range from 15 mm to 300 mm. Each size of the flange corresponds to specific outer diameter (OD), inner diameter (ID), and thickness measurements.

Pressure Rating

As stated earlier, the "10K" rating signifies that these flanges can withstand pressures up to 10 kg/cm². This rating is critical for applications requiring resilience against high-pressure conditions.

Material Composition

JIS B2220 10K flanges can be manufactured from several materials, with the most common being:

- **Carbon Steel**: Offers excellent strength and is widely used in industrial applications.

- **Stainless Steel**: Provides corrosion resistance, making it suitable for chemical and food processing industries.

- **Alloy Steel**: Often used in high-temperature applications, offering enhanced mechanical properties.

Surface Finish

The surface finish of JIS B2220 10K flanges can range from smooth to rough, depending on the manufacturer and the intended use. A smoother finish is often preferred for applications where minimizing friction is essential.

Applications of JIS B2220 10K Flange

The versatility of the JIS B2220 10K flange enables it to be utilized across various industries and applications. Some of the most common applications include:

Piping Systems in Chemical Industries

Chemical plants often use JIS B2220 10K flanges to connect pipes that transport aggressive fluids. The corrosion resistance of stainless steel flanges makes them particularly desirable in these environments.

Water Supply and Wastewater Treatment

These flanges are also employed in municipal water supply systems and wastewater treatment plants, where they facilitate the joining of pipes that transport large volumes of water.

Oil and Gas Industry

In the oil and gas sector, the JIS B2220 10K flange is used in pipelines that transfer crude oil, natural gas, and other hydrocarbons. The ability to withstand high pressures and harsh conditions makes this flange an ideal choice.

HVAC Systems

Heating, Ventilation, and Air Conditioning (HVAC) systems also incorporate JIS B2220 10K flanges for the connection of ductwork and pipes, ensuring efficient airflow and temperature control.

Benefits of Using JIS B2220 10K Flange

Choosing JIS B2220 10K flanges for pipeline connections comes with several benefits:

Durability and Strength

Constructed from high-quality materials, JIS B2220 10K flanges offer exceptional durability and strength. This robustness ensures they can withstand significant pressure and environmental stressors.

Corrosion Resistance

With options available in stainless steel, these flanges provide excellent resistance to corrosion. This property is crucial in applications where exposure to moisture or aggressive chemicals is a concern.

Ease of Installation

The design of JIS B2220 10K flanges allows for straightforward installation. The bolt holes facilitate easy alignment and fastening, reducing installation time and costs.

Versatility

These flanges can be used across a variety of industries, making them a versatile component in the construction of pipelines. This adaptability reduces the need for multiple types of flanges, streamlining inventory management.

Installation Techniques for JIS B2220 10K Flange

Proper installation is critical to ensuring the longevity and effectiveness of JIS B2220 10K flanges. Following these techniques can help achieve secure and leak-free connections.

Preparation of Flange Surfaces

Before installation, it is essential to clean the flange surfaces to remove any debris, oil, or rust. This prevents contamination and ensures a tight seal.

Alignment and Positioning

Align the flanges carefully to ensure that the bolt holes are directly opposite each other. Proper alignment prevents stress on the flanges, which could lead to failure.

Applying Gasket Material

Using a gasket material between the flanges can enhance sealing and prevent leaks. Select a gasket compatible with the fluids being transported to avoid deterioration.

Bolting Tightening Sequence

When tightening the bolts, follow a crisscross pattern to distribute pressure evenly across the flange. This technique minimizes the risk of warping and guarantees a secure connection.

Maintenance and Care for JIS B2220 10K Flange

Regular maintenance is vital to ensure the continued performance of JIS B2220 10K flanges. Here are some tips for care:

Routine Inspections

Conduct routine inspections of the flanges to check for any signs of wear, corrosion, or leaks. Early detection of issues can prevent catastrophic failures.

Cleaning

Keep the flanges clean by removing any debris or buildup. Use appropriate cleaning agents that will not damage the flange material.

Re-tightening Bolts

Over time, bolts may loosen due to vibrations or thermal expansion. Periodically re-tighten the bolts to maintain a secure connection.

Common Issues and Solutions

Despite their durability, JIS B2220 10K flanges can experience certain issues. Understanding these problems and their solutions can help maintain optimal performance.

Leakage

**Problem**: One of the most common issues is leakage due to improper installation or worn gaskets.

**Solution**: Inspect the installation for proper alignment and re-tighten the bolts. If the gasket is damaged, replace it with a new one.

Corrosion

**Problem**: Corrosion can occur, especially in environments with high moisture or aggressive chemicals.

**Solution**: Regularly inspect for signs of corrosion and consider applying protective coatings. If corrosion is severe, replacing the flange may be necessary.

Cracking

**Problem**: Cracks in the flange can develop due to excessive pressure or thermal stress.

**Solution**: If cracks are detected, immediately cease operation and replace the flange to prevent failure.

Frequently Asked Questions

**Q1: What is the maximum pressure rating for the JIS B2220 10K flange?**

A1: The maximum pressure rating for the JIS B2220 10K flange is 10 kg/cm².

**Q2: What materials are commonly used for JIS B2220 10K flanges?**

A2: Common materials include carbon steel, stainless steel, and alloy steel.

**Q3: How do I ensure a leak-free connection when installing a JIS B2220 10K flange?**

A3: Ensure proper alignment, use a compatible gasket, and follow the correct tightening sequence for bolts.

**Q4: Can I use JIS B2220 10K flanges in high-temperature applications?**

A4: Yes, certain materials like alloy steel are suitable for high-temperature applications.

**Q5: What maintenance is required for JIS B2220 10K flanges?**

A5: Regular inspections, routine cleaning, and re-tightening of bolts are essential for maintenance.

Conclusion

The **JIS B2220 10K flange** plays a pivotal role in ensuring safe and efficient pipeline connections across various industries. Understanding its specifications, applications, benefits, and installation techniques can significantly enhance the performance and reliability of your piping systems. By adhering to maintenance guidelines and promptly addressing any issues, users can extend the lifespan of these flanges, ensuring their critical function in fluid and gas transport remains uncompromised. Whether in chemical processing, water supply, or oil and gas applications, the JIS B2220 10K flange continues to be a trusted component in modern piping infrastructure.Related News

06 Jul,2025

JIS B2220 10K Flange: Bridging Gaps in Pipeline Connections

JIS B2220 10K Flange: Bridging Gaps in Pipeline Connections Pipeline systems are the backbone of various industries, facilitating the transportation of fluids and gases across vast distances. At the heart of these systems lie the components that ensure smooth and secure connections, among which the **JIS B2220 10K flange** stands out as a crucial element. In this article, we delve into the specifi

05 Jul,2025

Understanding BS10 Table D Flange: A Comprehensive Guide for Professionals

When working with piping systems, understanding the BS10 Table D flange is vital for professionals in the construction and decorative materials industry. The BS10 standard, established by the British Standards Institution (BSI), specifies the dimensions, tolerances, and pressure ratings for flanges used in various applications. Among the different types of flanges outlined in this standard, Table

04 Jul,2025

Why Choose Lap Joint Flanges for Your Piping Needs? A Comprehensive Guide

Why Choose Lap Joint Flanges for Your Piping Needs? When selecting components for your piping systems, the choice of flanges plays a crucial role in ensuring durability, efficiency, and safety. Among the various types of flanges available, lap joint flanges have gained popularity due to their unique design and practical advantages. In this comprehensive guide, we will explore the reasons to choose

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message