-

Exploring the Versatility of Lap Joint Flanges in Modern Applications

Date:

12 Jul,2025

Exploring the Versatility of Lap Joint Flanges in Modern Applications Introduction to Lap Joint Flanges In the realm of **construction and piping**, lap joint flanges have emerged as an essential component, offering a blend of versatility and reliability. Unlike standard flanges, lap joint flanges are designed to fit over a pipe and can be easily adjusted for alignment. This unique design makes th

Exploring the Versatility of Lap Joint Flanges in Modern Applications

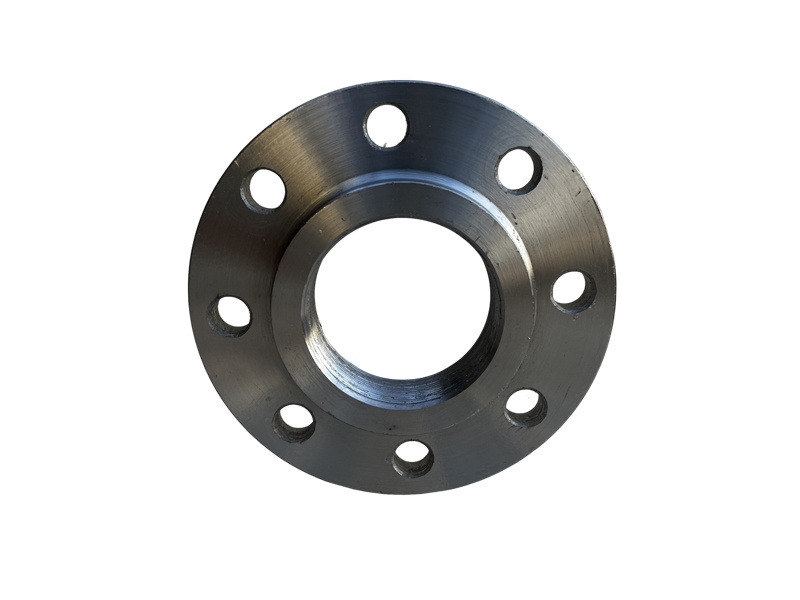

Introduction to Lap Joint Flanges

In the realm of **construction and piping**, lap joint flanges have emerged as an essential component, offering a blend of versatility and reliability. Unlike standard flanges, lap joint flanges are designed to fit over a pipe and can be easily adjusted for alignment. This unique design makes them particularly useful in applications where adjustments may be necessary during installation or maintenance.

The Anatomy of Lap Joint Flanges

Understanding the structure of lap joint flanges is crucial for appreciating their functionality. Typically, they consist of two main parts: the **flange** itself and the **stub end**.

Flange Design

The flange is characterized by its flat surface, which allows for a smooth connection to other components. It is often made from materials such as carbon steel or stainless steel, providing durability and resistance against corrosion.

Stub End Configuration

The stub end serves as the connecting piece that fits into the pipe. It is available in various configurations, such as **long** and **short**, catering to different operational requirements. This flexibility in design enhances the overall adaptability of the lap joint flange system.

Advantages of Using Lap Joint Flanges

Lap joint flanges come with a multitude of advantages, making them a preferred choice in various industrial applications.

Ease of Installation and Maintenance

One of the most significant benefits of lap joint flanges is their straightforward installation process. Their design allows for easier alignment, minimizing labor time and effort. Furthermore, maintenance operations are simplified, enabling quick disassembly and reassembly.

Versatility in Applications

The versatility of lap joint flanges extends beyond their ease of use. They can be employed in a wide range of industries, including:

- **Chemical Processing**: Ideal for systems that require frequent disassembly.

- **Water Treatment Facilities**: For quick repairs and adjustments.

- **Oil and Gas Industry**: Providing robust solutions in challenging environments.

Reduced Stress on Piping Systems

Lap joint flanges are engineered to distribute stress evenly across the piping system. This characteristic minimizes the risk of leaks and failures, particularly in high-pressure applications.

Corrosion Resistance

When made from stainless steel or other corrosion-resistant materials, lap joint flanges offer excellent resistance to environmental factors, extending the lifespan of the piping system.

Comparative Analysis: Lap Joint Flanges vs. Other Flange Types

While lap joint flanges have distinct advantages, it is vital to compare them with other common flange types to understand their unique position in the market.

Lap Joint Flanges vs. Weld Neck Flanges

Weld neck flanges are typically preferred for high-pressure applications due to their ability to withstand extreme conditions. However, lap joint flanges offer benefits in terms of ease of installation and disassembly, making them more suitable for applications requiring frequent maintenance.

Lap Joint Flanges vs. Slip-On Flanges

Slip-on flanges are easier to install than weld neck flanges but may not provide the same level of joint stability. Lap joint flanges, on the other hand, excel in applications where alignment adjustments are essential.

Choosing the Right Lap Joint Flange for Your Project

Selecting the appropriate lap joint flange requires careful consideration of various factors to ensure optimal performance and longevity.

Material Selection

The choice of material plays a pivotal role in the flange's performance. Factors such as temperature, pressure, and exposure to corrosive substances should guide the decision-making process. Common materials include:

- **Carbon Steel**: Cost-effective and suitable for moderate conditions.

- **Stainless Steel**: Ideal for high-corrosion environments.

- **Alloy Steel**: Offers enhanced strength and durability.

Size and Pressure Rating

Flanges come in various sizes and pressure ratings. It is crucial to choose a size that matches the diameter of the piping system and a pressure rating that meets or exceeds the system’s operational demands.

Installation Best Practices for Lap Joint Flanges

Installing lap joint flanges correctly is essential for maintaining the integrity of the piping system.

Preparation of Surfaces

Before installation, ensure that the surfaces of both the flange and the stub end are clean and free from debris. Any contaminants can compromise the seal and lead to potential leaks.

Correct Alignment

Proper alignment is crucial when installing lap joint flanges. Misalignment can lead to unnecessary stress on the flange, increasing the risk of failure. Use alignment tools and techniques to ensure a perfect fit.

Tightening Procedures

Follow proper tightening procedures when securing the flange. Use a star pattern for tightening bolts to ensure even pressure distribution. Over-tightening can damage the flange, while under-tightening may result in leaks.

Maintenance and Inspection of Lap Joint Flanges

Regular maintenance and inspection of lap joint flanges are vital for ensuring their longevity and performance.

Visual Inspections

Conduct visual inspections periodically to check for signs of wear, corrosion, or leaks. Early detection of potential issues can prevent costly repairs down the line.

Ultrasonic Testing

Ultrasonic testing is an effective non-destructive method to assess the integrity of lap joint flanges. This technique can identify hidden defects that may not be visible during a standard visual inspection.

Future Trends in Lap Joint Flange Technology

As industries evolve, so does the technology surrounding lap joint flanges. Innovations are continuously emerging to enhance their performance and applicability.

Smart Flange Technology

The integration of smart technologies into lap joint flanges is gaining traction. Smart flanges can monitor pressure, temperature, and fluid levels, providing real-time data to operators. This information is invaluable for predictive maintenance and operational efficiency.

Advanced Materials

Research is underway to develop advanced materials that further improve the durability and corrosion resistance of lap joint flanges. Innovations in composite materials may soon offer even greater advantages over traditional metal flanges.

FAQs About Lap Joint Flanges

What are lap joint flanges used for?

Lap joint flanges are primarily used in piping systems that require frequent disassembly, such as in the chemical processing and oil and gas industries.

How do lap joint flanges differ from other flanges?

Lap joint flanges feature a stub end that allows for easy alignment and adjustment, unlike other flanges that may require welding or more complex installation procedures.

What materials are lap joint flanges made from?

Common materials include carbon steel, stainless steel, and alloy steel, chosen based on the specific application and environmental conditions.

How can I ensure a proper installation of lap joint flanges?

Proper surface preparation, alignment, and adherence to tightening procedures are key to ensuring a successful installation of lap joint flanges.

Are lap joint flanges suitable for high-pressure applications?

While lap joint flanges can handle moderate pressure, for high-pressure applications, weld neck flanges may be a more suitable choice.

Conclusion

The versatility of lap joint flanges makes them an indispensable component in modern piping systems. Their ease of installation, adaptability, and robust performance set them apart from other flange types, making them suitable for a wide range of applications. As technology continues to evolve, lap joint flanges will likely see further enhancements that improve their function and efficiency, solidifying their role in the construction and industrial sectors. Whether you are involved in chemical processing, oil and gas, or water treatment, understanding the benefits and features of lap joint flanges will aid in making informed decisions for your projects.Related News

13 Jul,2025

Understanding BS10 Table D Flanges: Essential Insights for Construction and Decoration Materials

BS10 Table D flanges are a key component in various piping systems, primarily used in construction and decorative materials applications. These flanges are designed according to British Standard (BS) 10, which outlines the dimensions and pressure ratings for different flange types. Table D specifically refers to a particular set of dimensions that are widely used in conjunction with pipes of speci

12 Jul,2025

Exploring the Versatility of Lap Joint Flanges in Modern Applications

Exploring the Versatility of Lap Joint Flanges in Modern Applications Introduction to Lap Joint Flanges In the realm of **construction and piping**, lap joint flanges have emerged as an essential component, offering a blend of versatility and reliability. Unlike standard flanges, lap joint flanges are designed to fit over a pipe and can be easily adjusted for alignment. This unique design makes th

11 Jul,2025

Understanding Butt Weld Elbows: Essential Components for Your Construction Projects

Butt weld elbows are crucial components used in piping systems to facilitate changes in direction. These fittings are designed to create a seamless transition between two sections of pipe, allowing for smooth flow and reducing the risk of turbulence. By welding the elbow directly to the pipe, these fittings provide a strong and durable connection that can withstand high pressures and temperatures,

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message