-

Understanding BS10 Table D Flanges: Essential Insights for Construction and Decoration Materials

Date:

13 Jul,2025

BS10 Table D flanges are a key component in various piping systems, primarily used in construction and decorative materials applications. These flanges are designed according to British Standard (BS) 10, which outlines the dimensions and pressure ratings for different flange types. Table D specifically refers to a particular set of dimensions that are widely used in conjunction with pipes of speci

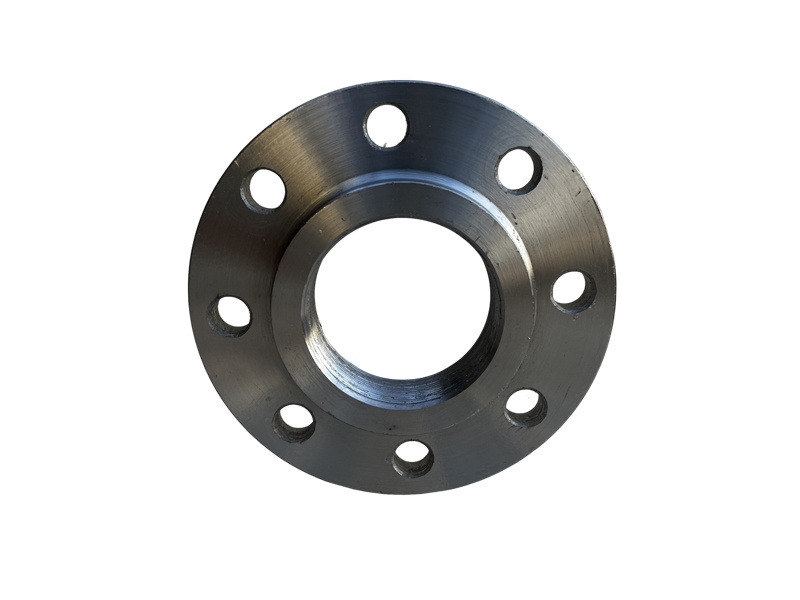

BS10 Table D flanges are a key component in various piping systems, primarily used in construction and decorative materials applications. These flanges are designed according to British Standard (BS) 10, which outlines the dimensions and pressure ratings for different flange types. Table D specifically refers to a particular set of dimensions that are widely used in conjunction with pipes of specific nominal sizes.

One of the fundamental characteristics of BS10 Table D flanges is their versatility. They can be made from various materials including carbon steel, stainless steel, and other alloys, which allows them to be used in different environments, from industrial applications to decorative installations. The selection of material often depends on the specific requirements such as resistance to corrosion, temperature, and pressure.

In terms of dimensions, BS10 Table D flanges are characterized by their bolt hole configuration, which allows for secure fastening to pipes, valves, and other components. The standard dimensions include the outer diameter, bolt circle diameter, and the size of the bolt holes, which are crucial for ensuring a proper fit. Understanding these specifications is essential for engineers and architects when designing systems that require precise connections.

Another significant aspect of BS10 Table D flanges is their pressure rating, which indicates the maximum pressure the flange can withstand under specific conditions. This rating is vital when choosing flanges for high-pressure applications, as it ensures safety and reliability in the overall system. It is essential to match the flange’s pressure rating with that of the piping system to avoid potential failures.

Additionally, BS10 Table D flanges are often used in conjunction with gaskets to ensure a leak-proof seal between two surfaces. The choice of gasket material should also be considered based on the application environment, as it plays a critical role in maintaining the integrity of the connection.

Installation of BS10 Table D flanges requires careful attention to detail. Proper alignment and the use of torque specifications during fastening are crucial to achieve a secure connection. Inadequate installation can lead to leaks or even catastrophic failures in piping systems.

In conclusion, BS10 Table D flanges are an indispensable component in the construction and decoration materials industry. Their standardized dimensions, pressure ratings, and versatility make them suitable for a wide range of applications. Understanding the specifications and proper installation techniques for these flanges is vital for ensuring the safety and efficiency of piping systems. By familiarizing yourself with BS10 Table D flanges, you can enhance your expertise and contribute to successful project outcomes in your field.Related News

13 Jul,2025

Understanding BS10 Table D Flanges: Essential Insights for Construction and Decoration Materials

BS10 Table D flanges are a key component in various piping systems, primarily used in construction and decorative materials applications. These flanges are designed according to British Standard (BS) 10, which outlines the dimensions and pressure ratings for different flange types. Table D specifically refers to a particular set of dimensions that are widely used in conjunction with pipes of speci

12 Jul,2025

Exploring the Versatility of Lap Joint Flanges in Modern Applications

Exploring the Versatility of Lap Joint Flanges in Modern Applications Introduction to Lap Joint Flanges In the realm of **construction and piping**, lap joint flanges have emerged as an essential component, offering a blend of versatility and reliability. Unlike standard flanges, lap joint flanges are designed to fit over a pipe and can be easily adjusted for alignment. This unique design makes th

11 Jul,2025

Understanding Butt Weld Elbows: Essential Components for Your Construction Projects

Butt weld elbows are crucial components used in piping systems to facilitate changes in direction. These fittings are designed to create a seamless transition between two sections of pipe, allowing for smooth flow and reducing the risk of turbulence. By welding the elbow directly to the pipe, these fittings provide a strong and durable connection that can withstand high pressures and temperatures,

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message