-

BS10 Table D Flanges: The Backbone of Reliable Pipe Systems

Date:

07 Jan,2026

BS10 Table D Flanges: The Backbone of Reliable Pipe Systems Introduction to BS10 Table D Flanges In the world of piping systems, flanges play a crucial role in ensuring the integrity and reliability of connections. Among the various types of flanges, **BS10 Table D Flanges** stand out for their strength and versatility. These flanges are integral to various applications, providing essential supp

BS10 Table D Flanges: The Backbone of Reliable Pipe Systems

Introduction to BS10 Table D Flanges

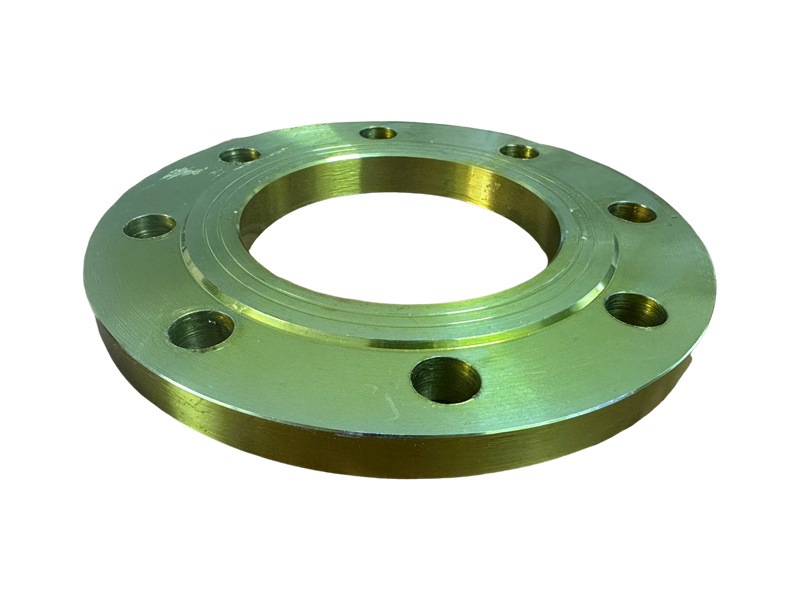

In the world of piping systems, flanges play a crucial role in ensuring the integrity and reliability of connections. Among the various types of flanges, **BS10 Table D Flanges** stand out for their strength and versatility. These flanges are integral to various applications, providing essential support for pipes and fittings in numerous industries.

Understanding Flanges and Their Importance

Flanges are mechanical components that serve as a connection point between two pipes or fittings. They allow for easy assembly and disassembly, making maintenance and repairs more manageable. The importance of flanges cannot be overstated; they help maintain the stability of a piping system, prevent leaks, and support processes in different sectors, including water treatment, oil and gas, and construction.

The Role of BS10 Table D Flanges

**BS10 Table D Flanges** are specifically designed to meet the requirements of British Standard 10 (BS10), which outlines the dimensions and specifications for various flange types. These flanges are characterized by their **robust construction** and ability to withstand high-pressure environments. As such, they are often used in applications that require secure and durable connections, such as in **chemical processing facilities** and **commercial plumbing systems.**

Specifications of BS10 Table D Flanges

Understanding the specifications of BS10 Table D Flanges is essential for selecting the right flange for your application. Here are key specifications to consider:

Material Composition

BS10 Table D Flanges are typically manufactured from various materials, including:

- **Carbon Steel:** Known for its strength and durability, carbon steel flanges are suitable for high-pressure applications.

- **Stainless Steel:** Resistant to corrosion, stainless steel flanges are ideal for environments exposed to moisture or chemicals.

- **Alloy Steel:** Often used in high-temperature applications, alloy steel flanges provide enhanced mechanical properties.

Dimensions

The dimensions of BS10 Table D Flanges adhere to the standards set by the British Standards Institution (BSI). They typically include:

- **Bolt Hole Diameter:** The size of the holes for bolts, which is crucial for ensuring a secure connection.

- **Nominal Size:** The size designation that indicates the diameter of the pipe the flange will connect to.

- **Thickness:** The thickness of the flange itself, which affects its strength and pressure rating.

Pressure Ratings

BS10 Table D Flanges are available in various pressure ratings, allowing them to be used in different environments. Common pressure ratings include:

- **PN10:** Suitable for low-pressure applications.

- **PN16:** Ideal for moderate pressure systems.

- **PN25:** Designed for high-pressure applications.

Applications of BS10 Table D Flanges

BS10 Table D Flanges find applications across various industries, showcasing their versatility:

Oil and Gas Industry

In the oil and gas sector, BS10 Table D Flanges are vital for ensuring secure connections in pipelines that transport crude oil and natural gas. Their ability to withstand high pressures makes them ideal for use in extraction and refining processes.

Water Treatment Facilities

Water treatment facilities rely on BS10 Table D Flanges for connecting various components in their systems. These flanges help maintain the integrity of water pipelines, ensuring efficient water distribution and treatment processes.

Construction Projects

In construction, BS10 Table D Flanges are used in plumbing systems and other essential infrastructure. They provide reliable connections in heating, ventilation, and air conditioning (HVAC) systems, ensuring optimal performance.

Benefits of Using BS10 Table D Flanges

Choosing BS10 Table D Flanges comes with numerous benefits that enhance their appeal in various applications:

Durability and Longevity

BS10 Table D Flanges are designed to withstand harsh conditions, making them an excellent choice for long-term use. Their robust construction ensures they can handle high pressures and temperatures without compromising performance.

Ease of Installation

One of the significant advantages of BS10 Table D Flanges is their straightforward installation process. They allow for easy assembly and disassembly, facilitating maintenance and repair tasks without the need for specialized tools.

Versatile Compatibility

These flanges are compatible with a wide range of pipe materials and sizes, making them a versatile choice for various piping systems. This compatibility ensures they can be integrated seamlessly into existing infrastructure.

Installation Guidelines for BS10 Table D Flanges

Proper installation is crucial to maximizing the performance of BS10 Table D Flanges. Here are some essential guidelines:

Tools Required

Before starting the installation, gather the necessary tools, including:

- **Wrenches:** For tightening bolts securely.

- **Gaskets:** To ensure a leak-proof seal between flanges.

- **Torque Wrench:** To apply the correct torque to the bolts.

Preparation Steps

1. **Inspect the Flanges:** Check for any imperfections or damage that may affect performance.

2. **Clean the Surface:** Ensure that the surfaces of both flanges are clean and free from debris.

3. **Align the Flanges:** Position the flanges together, ensuring that bolt holes align correctly.

Tightening the Bolts

Use a **star pattern** when tightening bolts to ensure even pressure distribution. Begin with a lower torque setting, gradually increasing to the recommended torque for the specific flange type.

Maintenance Tips for BS10 Table D Flanges

To ensure the longevity and performance of BS10 Table D Flanges, implement regular maintenance practices:

Routine Inspections

Conduct routine inspections to identify any signs of wear or corrosion. Early detection can prevent leaks and failures.

Cleaning Procedures

Regularly clean the flanges to remove any dirt, grime, or build-up that can affect performance. Use appropriate cleaning agents that won’t damage the flange material.

Re-Torquing Bolts

Check and re-torque bolts periodically, especially in high-pressure or fluctuating temperature environments. This practice helps maintain a secure connection and prevents leaks.

Common Misconceptions About BS10 Table D Flanges

There are several misconceptions surrounding BS10 Table D Flanges that can lead to misunderstandings:

They Are Only for High-Pressure Applications

While BS10 Table D Flanges are suitable for high-pressure environments, they are also versatile enough for low and moderate pressure applications. Their wide range of pressure ratings makes them adaptable.

Installation Requires Specialized Tools

Contrary to popular belief, installing BS10 Table D Flanges does not require specialized tools. Basic tools such as wrenches and torque wrenches are sufficient for proper installation.

Frequently Asked Questions (FAQs)

1. What is the difference between BS10 Table D Flanges and other flange types?

BS10 Table D Flanges adhere to specific British Standards, offering unique dimensions and pressure ratings that differentiate them from other types of flanges, such as ANSI or DIN flanges.

2. Can BS10 Table D Flanges be used in corrosive environments?

Yes, when made from stainless steel or other corrosion-resistant materials, BS10 Table D Flanges are suitable for use in corrosive environments.

3. How do I choose the right size BS10 Table D Flange?

Selecting the proper size involves matching the flange size to the nominal size of the pipe it will connect to, as well as considering the bolt hole diameter and pressure rating.

4. Are BS10 Table D Flanges reusable?

Yes, BS10 Table D Flanges can be reused if they are in good condition and have not been subjected to excessive wear or damage.

5. What maintenance is required for BS10 Table D Flanges?

Regular inspections, cleaning, and re-torquing of bolts are essential maintenance practices to ensure the longevity and performance of BS10 Table D Flanges.

Conclusion

BS10 Table D Flanges are undeniably the backbone of reliable pipe systems. Their robust specifications, versatility, and ease of installation make them an essential component in various applications. By understanding their features, benefits, and maintenance requirements, industry professionals can ensure the efficiency and longevity of their piping systems. Investing in high-quality BS10 Table D Flanges not only enhances the durability of your piping infrastructure but also contributes to the overall effectiveness of your operations.Related News

15 Jan,2026

Top Applications of GOST Slip-On Flanges in Architecture The world of architecture is constantly evolving, with materials and techniques that enhance both functionality and aesthetics. One of the essential components in modern construction is the **GOST Slip-On Flange**, a type of fitting that plays a crucial role in connecting pipes and enhancing structural integrity. This article explores the **

13 Jan,2026

Understanding Concentric Reducers: Essential Components in Pipe Fitting

Concentric reducers are critical components in the realm of pipe fittings, playing a significant role in various plumbing and HVAC applications. These fittings facilitate the transition between pipes of different diameters while maintaining a smooth flow path. The design of concentric reducers allows them to connect a larger pipe to a smaller pipe, creating a seamless connection that minimizes tur

11 Jan,2026

Key Considerations When Working with JIS B2220 10K Flange: A Comprehensive Guide

Key Considerations When Working with JIS B2220 10K Flange When it comes to piping systems in various industries, JIS B2220 10K flanges are critical components. These flanges provide not only a means to connect piping but also ensure leak-tight connections under different pressures and temperatures. In this guide, we will explore several key considerations when working with JIS B2220 10K flanges, i

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message