-

Key Considerations When Working with JIS B2220 10K Flange: A Comprehensive Guide

Date:

11 Jan,2026

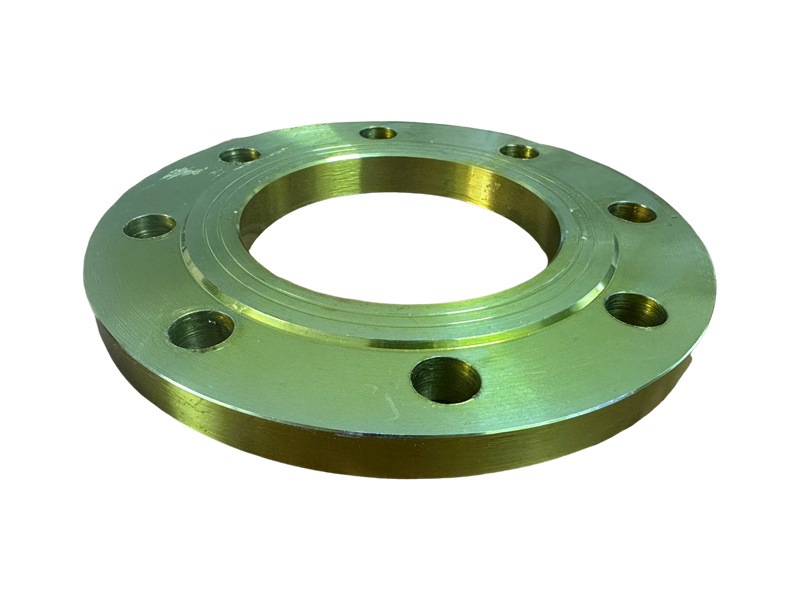

Key Considerations When Working with JIS B2220 10K Flange When it comes to piping systems in various industries, JIS B2220 10K flanges are critical components. These flanges provide not only a means to connect piping but also ensure leak-tight connections under different pressures and temperatures. In this guide, we will explore several key considerations when working with JIS B2220 10K flanges, i

Key Considerations When Working with JIS B2220 10K Flange

When it comes to piping systems in various industries, JIS B2220 10K flanges are critical components. These flanges provide not only a means to connect piping but also ensure leak-tight connections under different pressures and temperatures. In this guide, we will explore several key considerations when working with JIS B2220 10K flanges, including their specifications, materials, installation, and maintenance. The goal is to give you a comprehensive understanding that enhances your project’s success.

Table of Contents

- Understanding JIS B2220 10K Flange

- Applications of JIS B2220 10K Flange

- Specifications of JIS B2220 10K Flange

- Material Choices for JIS B2220 10K Flange

- Installation Best Practices

- Maintenance and Inspection

- Common Issues and Troubleshooting

- Conclusion

Understanding JIS B2220 10K Flange

The JIS B2220 standard originates from Japan and defines the specifications for flanges used in piping systems. The “10K” designation indicates the flange’s pressure rating, which is 10 kg/cm² or approximately 145 psi. JIS B2220 10K flanges are typically used in water supply, chemical processing, and other applications that require reliable connections in moderate-pressure environments.

The Importance of Flanges in Piping Systems

Flanges play a vital role in the integrity of piping systems. They enable easy dismantling and allow for the adjustment of pipe alignment, making maintenance and repairs simpler. Additionally, they are crucial for ensuring a leak-proof seal, which is essential in preventing accidents and environmental hazards.

Applications of JIS B2220 10K Flange

JIS B2220 10K flanges find their applications across various sectors. Here are some key areas where they are commonly used:

Water Treatment Facilities

In water treatment plants, JIS B2220 10K flanges are used to connect pipelines transporting various water types. Their ability to withstand pressure ensures they can handle the demands of water flow without leakage.

Petrochemical Industries

These flanges are also prevalent in petrochemical facilities, where they connect pipes carrying oils and chemicals. Their resistance to corrosion and ability to maintain integrity under varying temperatures make them ideal for this application.

Construction and Infrastructure

In the construction industry, JIS B2220 10K flanges are used in plumbing systems, HVAC installations, and fire protection systems. They provide a secure connection point for various pipes involved in these systems.

Specifications of JIS B2220 10K Flange

Understanding the specifications of JIS B2220 10K flanges is crucial for ensuring compatibility within your system. Here are the key specifications you should know:

Dimensions and Pressure Ratings

JIS B2220 10K flanges come in various sizes, typically ranging from 15 mm to 600 mm. The pressure rating of 10K indicates that these flanges can handle pressures up to 10 kg/cm². It is essential to choose the right size and pressure rating based on your specific application requirements.

Flange Types

JIS B2220 10K flanges are available in several types, including:

- **Flat Flange**: Most common, providing a flat surface for sealing against a corresponding flat surface.

- **Raised Face Flange**: Features a raised area for a better seal.

- **Blind Flange**: Used to close off a piping system.

Each type serves different purposes within a piping system, and selecting the appropriate type is vital for ensuring optimal performance.

Material Choices for JIS B2220 10K Flange

The materials used in the construction of JIS B2220 10K flanges significantly affect their performance. Common materials include:

Carbon Steel

Carbon steel flanges offer high strength and durability, making them suitable for many applications. They are often coated or galvanized to enhance corrosion resistance.

Stainless Steel

Stainless steel flanges resist corrosion more effectively than carbon steel, making them ideal for chemical and marine applications. They come in various grades, with 304 and 316 being the most common.

Ductile Iron

Ductile iron flanges exhibit high tensile strength and impact resistance, making them suitable for heavy-duty applications. They are commonly used in waterworks and sewage systems.

Installation Best Practices

Proper installation of JIS B2220 10K flanges is crucial for ensuring a leak-free and reliable piping system. Here are some best practices to follow:

Surface Preparation

Before installation, ensure that the surfaces of both the flange and the adjoining pipe are clean and free of debris. Any dirt or residue can compromise the seal and lead to leaks.

Use of Gaskets

Always use a compatible gasket when installing flanges. Gaskets help create a tight seal and prevent leakage. Choose gaskets made from materials that suit your system's pressure and temperature requirements.

Torque Specifications

Follow the manufacturer's torque specifications when tightening the flange bolts. Over-tightening can lead to flange deformation, while under-tightening can cause leaks.

Maintenance and Inspection

Regular maintenance and inspection of JIS B2220 10K flanges are essential to ensure their longevity and performance. Here are some tips on how to maintain and inspect your flanges effectively:

Routine Inspections

Conduct routine inspections for signs of wear, corrosion, or leaks. Early detection of issues can prevent costly repairs and ensure system integrity.

Cleaning

Keep the flanges clean and free from any buildup of materials that may impact their performance. Use appropriate cleaning agents that do not damage the flange material.

Replacement of Worn Components

If you notice any wear or damage during inspections, replace worn components immediately. This precaution helps maintain the reliability of your piping system.

Common Issues and Troubleshooting

Understanding common problems associated with JIS B2220 10K flanges can help you troubleshoot effectively. Here are some issues to look out for:

Leaking Connections

Leaking is one of the most common issues with flanges. Ensure that the gasket is installed correctly and that the bolts are tightened to the specified torque. If leaks persist, check for surface damage or corrosion.

Corrosion

Corrosion can weaken the integrity of flanges over time. To prevent this, choose the right material for your application and consider protective coatings.

Misalignment

Misalignment of flanges can lead to stress and potential failure. Ensure proper alignment during installation, and use flexible pipe connectors if necessary.

Conclusion

Working with JIS B2220 10K flanges requires a thorough understanding of their specifications, materials, applications, and installation practices. By following this comprehensive guide, you can ensure optimal performance and longevity in your piping systems. Whether it's for water treatment, petrochemical processing, or construction, proper attention to detail and maintenance can prevent issues and enhance the overall efficiency of your project. Making informed choices in flange selection and installation will pay off in the reliability and safety of your systems.

FAQs

1. What is the pressure rating of JIS B2220 10K flanges?

The pressure rating of JIS B2220 10K flanges is 10 kg/cm² or approximately 145 psi.

2. What materials are commonly used for JIS B2220 10K flanges?

Common materials include carbon steel, stainless steel, and ductile iron.

3. How do I ensure a leak-proof seal when installing flanges?

Use the correct gasket material and follow proper torque specifications when tightening bolts.

4. What are the common applications for JIS B2220 10K flanges?

They are widely used in water treatment facilities, petrochemical industries, and construction projects.

5. How often should I inspect JIS B2220 10K flanges?

Regular inspections should be performed as part of routine maintenance to detect any signs of wear or damage early.Related News

15 Jan,2026

Top Applications of GOST Slip-On Flanges in Architecture The world of architecture is constantly evolving, with materials and techniques that enhance both functionality and aesthetics. One of the essential components in modern construction is the **GOST Slip-On Flange**, a type of fitting that plays a crucial role in connecting pipes and enhancing structural integrity. This article explores the **

13 Jan,2026

Understanding Concentric Reducers: Essential Components in Pipe Fitting

Concentric reducers are critical components in the realm of pipe fittings, playing a significant role in various plumbing and HVAC applications. These fittings facilitate the transition between pipes of different diameters while maintaining a smooth flow path. The design of concentric reducers allows them to connect a larger pipe to a smaller pipe, creating a seamless connection that minimizes tur

11 Jan,2026

Key Considerations When Working with JIS B2220 10K Flange: A Comprehensive Guide

Key Considerations When Working with JIS B2220 10K Flange When it comes to piping systems in various industries, JIS B2220 10K flanges are critical components. These flanges provide not only a means to connect piping but also ensure leak-tight connections under different pressures and temperatures. In this guide, we will explore several key considerations when working with JIS B2220 10K flanges, i

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message