-

Top Applications of GOST Slip-On Flanges in Architecture: Enhancing Structural Integrity and Aesthetics

Date:

15 Jan,2026

Top Applications of GOST Slip-On Flanges in Architecture The world of architecture is constantly evolving, with materials and techniques that enhance both functionality and aesthetics. One of the essential components in modern construction is the **GOST Slip-On Flange**, a type of fitting that plays a crucial role in connecting pipes and enhancing structural integrity. This article explores the **

Top Applications of GOST Slip-On Flanges in Architecture

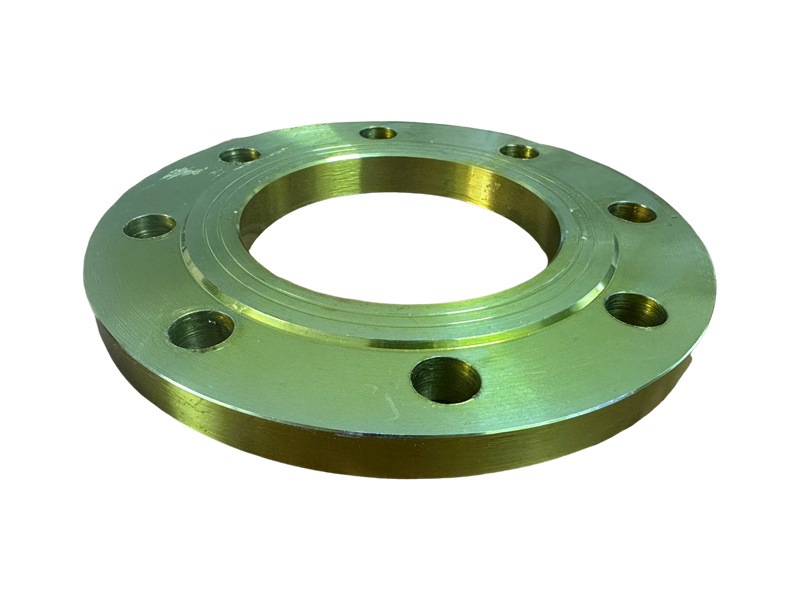

The world of architecture is constantly evolving, with materials and techniques that enhance both functionality and aesthetics. One of the essential components in modern construction is the **GOST Slip-On Flange**, a type of fitting that plays a crucial role in connecting pipes and enhancing structural integrity. This article explores the **top applications of GOST Slip-On Flanges** in architecture, showcasing their diverse uses, benefits, and contributions to contemporary design.

Understanding GOST Slip-On Flanges

Before diving into their applications, it's vital to understand what GOST Slip-On Flanges are. These flanges are designed to slip over the end of a pipe, allowing for easy installation and a secure connection. They are made according to the **GOST (Gosudarstvennyy Standart)** standards, which are a set of technical regulations in Russia that ensure quality and compatibility in various materials and components.

Why Choose GOST Slip-On Flanges?

GOST Slip-On Flanges offer several advantages that make them a popular choice among architects and engineers:

1. **Ease of Installation**: Their design allows for straightforward installation, reducing labor costs and time.

2. **Versatility**: They can be used in various applications, from plumbing to structural frameworks.

3. **Cost-Effectiveness**: GOST Slip-On Flanges are generally more affordable than other types of flanges, making them an economical option for large projects.

4. **Strength and Durability**: Made from high-quality materials, they provide excellent strength and resistance to corrosion.

Key Applications of GOST Slip-On Flanges in Architecture

The applications of GOST Slip-On Flanges are vast, and they play an essential role in numerous architectural projects. Below are the primary areas where these flanges excel:

1. Plumbing Systems

In plumbing systems, GOST Slip-On Flanges are widely used to connect various pipe sections. Their ability to provide a secure and leak-proof connection is paramount in ensuring efficient water supply and drainage systems.

Benefits in Plumbing

- **Enhanced Leak Resistance**: Their design minimizes the risk of leaks, ensuring long-lasting performance.

- **Simplified Maintenance**: Easy access for repairs or replacements makes them a preferred choice.

2. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely heavily on effective piping connections. GOST Slip-On Flanges offer a reliable solution for connecting ductwork and piping systems, ensuring optimal airflow and temperature regulation.

The Role of Flanges in HVAC

- **Facilitated Installation**: Their ease of installation reduces downtime during HVAC system setups.

- **Improved Efficiency**: A tight seal enhances the overall performance of HVAC systems by preventing air loss.

3. Structural Applications

In structural applications, GOST Slip-On Flanges are often used to connect steel beams and columns. This connection is crucial for ensuring the stability and strength of the entire structure.

Impact on Structural Integrity

- **Increased Load-Bearing Capacity**: They enhance the load-bearing capacity of structures, making them ideal for high-rise buildings.

- **Flexibility in Design**: Architects can incorporate them seamlessly into various designs without sacrificing aesthetics.

4. Industrial Applications

Industrial facilities frequently utilize GOST Slip-On Flanges in their piping systems. From processing plants to refineries, these flanges help maintain the integrity of complex piping networks.

Advantages in Industrial Settings

- **Safety Assurance**: Their robust design ensures safety in operations, especially in high-pressure environments.

- **Compatibility with Various Materials**: They can be used with multiple materials, providing versatility in industrial applications.

5. Fire Protection Systems

Fire protection systems also benefit from the use of GOST Slip-On Flanges. These flanges secure connections between pipes that transport fire suppression agents, ensuring that systems work effectively during emergencies.

Critical Benefits for Fire Safety

- **Reliable Connectivity**: Their dependable connections help ensure that fire suppression systems operate as intended.

- **Durability in Extreme Conditions**: GOST Slip-On Flanges are designed to withstand harsh conditions, enhancing the reliability of fire protection systems.

Choosing the Right GOST Slip-On Flange for Your Project

Selecting the appropriate GOST Slip-On Flange requires consideration of several factors:

1. Material Selection

GOST Slip-On Flanges are available in various materials, including carbon steel, stainless steel, and alloy metals. The choice of material should align with the project's specific requirements, such as pressure ratings and environmental conditions.

2. Size and Dimensions

Proper sizing is critical to ensure a secure fit and optimal performance. Always consult the specifications of both the pipe and the flange to ensure compatibility.

3. Pressure Rating

Understanding the pressure rating of the flanges is essential, particularly in applications involving high pressure or temperature. Ensure the chosen flange meets or exceeds the operational pressure requirements.

4. Standards and Certifications

Always check that the GOST Slip-On Flanges meet relevant standards and certifications. Compliance with these regulations ensures quality and safety in your construction project.

Installation Process for GOST Slip-On Flanges

Installing GOST Slip-On Flanges is relatively straightforward but must adhere to best practices to ensure long-lasting performance. Here’s a step-by-step guide:

Step 1: Preparation

Ensure that the ends of the pipes are clean and free from debris. This step is crucial for achieving a tight seal.

Step 2: Positioning the Flange

Align the slip-on flange with the pipe end, ensuring it is centered and level.

Step 3: Welding

Weld the flange to the pipe, ensuring that the weld is complete and secure. This step enhances the connection's strength.

Step 4: Testing

After installation, conduct a pressure test to ensure that the connection is leak-proof and functioning correctly.

Maintenance of GOST Slip-On Flanges

Regular maintenance is essential for ensuring the longevity and effectiveness of GOST Slip-On Flanges:

1. Inspection

Periodically inspect the flanges for signs of wear, corrosion, or damage. Early detection can prevent more severe issues down the line.

2. Cleaning

Keep the flanges clean to prevent buildup that could compromise their integrity. Use appropriate cleaning agents that won’t corrode the material.

3. Tightening Bolts

Regularly check and tighten the bolts connecting the flanges. Loose bolts can lead to leaks and compromised connections.

Conclusion

GOST Slip-On Flanges serve as a vital component in the architecture and construction industries, providing reliable, efficient, and durable connections across various applications. Their versatility spans plumbing, HVAC systems, structural frameworks, industrial settings, and fire protection systems, making them indispensable in modern architectural design. By understanding their applications, benefits, and maintenance needs, architects and engineers can leverage GOST Slip-On Flanges to enhance both functionality and aesthetics in their projects. Embracing these flanges will undoubtedly lead to improvements in structural integrity and overall project success.

Frequently Asked Questions (FAQs)

1. What are GOST Slip-On Flanges used for?

GOST Slip-On Flanges are primarily used to connect pipes in various systems including plumbing, HVAC, structural frameworks, and industrial applications.

2. How do I choose the right GOST Slip-On Flange?

Consider factors such as material, size, pressure rating, and compliance with standards when selecting a GOST Slip-On Flange.

3. Are GOST Slip-On Flanges easy to install?

Yes, they are designed for easy installation, allowing for quick connections and reducing labor costs.

4. What materials are GOST Slip-On Flanges made from?

They are typically made from carbon steel, stainless steel, and various alloy metals, depending on the application requirements.

5. How often should GOST Slip-On Flanges be inspected?

Regular inspections are recommended to identify any signs of wear or damage, ideally every six months or as dictated by project safety regulations.Related News

19 Jan,2026

The Cost Benefits of Using Steel Concentric Reducers in Large Projects

The Cost Benefits of Using Steel Concentric Reducers in Large Projects Introduction to Steel Concentric Reducers Steel concentric reducers are crucial components in piping systems, specifically designed to facilitate the transition between different pipe diameters. As construction and industrial projects grow in complexity, understanding the benefits of using these fittings can lead to substantial

17 Jan,2026

--- Forged steel elbows are integral components in piping systems, widely used in various industries, including construction and decorative materials. These fittings allow for directional changes in piping and provide a way to connect different sections of piping while maintaining a smooth flow of fluids. Understanding their properties, applications, and benefits is essential for professionals in

15 Jan,2026

Top Applications of GOST Slip-On Flanges in Architecture The world of architecture is constantly evolving, with materials and techniques that enhance both functionality and aesthetics. One of the essential components in modern construction is the **GOST Slip-On Flange**, a type of fitting that plays a crucial role in connecting pipes and enhancing structural integrity. This article explores the **

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message