-

The Cost Benefits of Using Steel Concentric Reducers in Large Projects

Date:

19 Jan,2026

The Cost Benefits of Using Steel Concentric Reducers in Large Projects Introduction to Steel Concentric Reducers Steel concentric reducers are crucial components in piping systems, specifically designed to facilitate the transition between different pipe diameters. As construction and industrial projects grow in complexity, understanding the benefits of using these fittings can lead to substantial

The Cost Benefits of Using Steel Concentric Reducers in Large Projects

Introduction to Steel Concentric Reducers

Steel concentric reducers are crucial components in piping systems, specifically designed to facilitate the transition between different pipe diameters. As construction and industrial projects grow in complexity, understanding the benefits of using these fittings can lead to substantial savings and improved project efficiency.

Understanding the Functionality of Steel Concentric Reducers

Steel concentric reducers primarily serve to connect pipes of varying sizes, enabling the smooth flow of fluids or gases. They are engineered to maintain a consistent flow profile, thereby minimizing turbulence and energy loss. This section will explore the structural integrity and performance characteristics that make steel concentric reducers a preferred choice in large projects.

Materials Matter: Why Choose Steel?

The choice of material is paramount in ensuring the longevity and durability of piping systems. Steel is favored for its strength, resistance to corrosion, and ability to withstand high pressure. This subsection will detail the advantages of steel over other materials like PVC and copper, emphasizing its cost-effectiveness in long-term applications.

Comparative Analysis: Steel Concentric Reducers vs. Other Reducer Types

When selecting reducers, it is essential to evaluate different types, including eccentric reducers and fabricated reducers. Here, we will compare steel concentric reducers with these alternatives, pointing out the unique benefits steel offers in terms of performance, maintenance, and cost.

Cost Efficiency: A Deep Dive into Financial Benefits

In large projects, every decision can affect the overall budget. Therefore, understanding the cost implications of using steel concentric reducers is vital.

Initial Investment vs. Long-Term Savings

While the upfront cost of steel concentric reducers may be higher compared to plastic alternatives, the long-term savings can be significant. We will analyze factors such as longevity, reduced maintenance costs, and lower risk of failure, providing a comprehensive view of the total cost of ownership.

Reducing Operational Costs with Efficient Design

The design of steel concentric reducers promotes optimal flow characteristics. By reducing friction and minimizing pressure drops, these fittings can lead to lower energy consumption in pumping systems. This section will highlight how efficient design can translate into operational cost savings.

Installation Benefits of Steel Concentric Reducers

Installation plays a critical role in the overall cost-benefit analysis of any construction component. Steel concentric reducers offer several advantages that can streamline the installation process.

Ease of Installation: A Time-Saving Advantage

Steel concentric reducers are typically easier to install due to their uniform shape and standardized sizes. This subsection will explore how ease of installation contributes to reduced labor costs and project timelines.

Compatibility with Existing Systems

In many large projects, the ability to seamlessly integrate new components with existing piping systems is crucial. Steel concentric reducers are designed for compatibility, which can significantly reduce the complexity of retrofitting or upgrading existing infrastructure.

Case Studies: Successful Implementation in Large Projects

Understanding real-world applications can provide insight into the effectiveness of steel concentric reducers. In this section, we will present several case studies that demonstrate how large projects have benefitted from using these fittings, showcasing both financial and operational successes.

Case Study 1: Industrial Facility Upgrade

We will examine an industrial facility that underwent a major upgrade, detailing how the implementation of steel concentric reducers led to enhanced efficiency and significant cost savings.

Case Study 2: Infrastructure Development Project

This case study will focus on a large-scale infrastructure project, illustrating the different challenges faced and how steel concentric reducers played a vital role in overcoming them.

Environmental Considerations and Sustainability

As sustainability becomes a focal point in construction, the environmental impact of materials used is under scrutiny. Steel is recyclable and often sourced responsibly, making it a sound choice for eco-conscious projects.

The Role of Steel in Sustainable Construction

This subsection will discuss the sustainability of steel concentric reducers and how their durability contributes to reducing waste in construction projects.

Energy Efficiency and Reduced Carbon Footprint

We will analyze how the use of steel concentric reducers can lead to greater energy efficiency, ultimately reducing the carbon footprint of large projects.

FAQs Regarding Steel Concentric Reducers

1. What is the primary function of steel concentric reducers?

The primary function of steel concentric reducers is to connect pipes of different diameters while maintaining a smooth flow of fluids or gases.

2. How do steel concentric reducers compare to plastic alternatives?

Steel concentric reducers are generally more durable, corrosion-resistant, and capable of withstanding higher pressures than plastic alternatives, making them suitable for more demanding applications.

3. What are the cost implications of using steel concentric reducers?

While the initial cost may be higher, steel concentric reducers offer long-term savings through enhanced durability, reduced maintenance needs, and improved energy efficiency.

4. Are steel concentric reducers easy to install?

Yes, steel concentric reducers are typically easy to install due to their standardized sizing and uniform design, leading to potential labor savings.

5. How do steel concentric reducers contribute to sustainability in construction?

Steel is a recyclable material, and using durable fittings like steel concentric reducers reduces waste, contributing to more sustainable construction practices.

Conclusion: Maximizing Value with Steel Concentric Reducers

In summary, the use of steel concentric reducers in large projects offers numerous **cost benefits** that extend beyond initial investment. Their durability, efficiency, and ease of installation make them an ideal choice for construction professionals aiming to optimize their project outcomes. By understanding and leveraging these advantages, stakeholders can significantly enhance the **overall performance** and **sustainability** of their projects, ensuring long-term success in an increasingly competitive landscape.Related News

19 Jan,2026

The Cost Benefits of Using Steel Concentric Reducers in Large Projects

The Cost Benefits of Using Steel Concentric Reducers in Large Projects Introduction to Steel Concentric Reducers Steel concentric reducers are crucial components in piping systems, specifically designed to facilitate the transition between different pipe diameters. As construction and industrial projects grow in complexity, understanding the benefits of using these fittings can lead to substantial

17 Jan,2026

--- Forged steel elbows are integral components in piping systems, widely used in various industries, including construction and decorative materials. These fittings allow for directional changes in piping and provide a way to connect different sections of piping while maintaining a smooth flow of fluids. Understanding their properties, applications, and benefits is essential for professionals in

15 Jan,2026

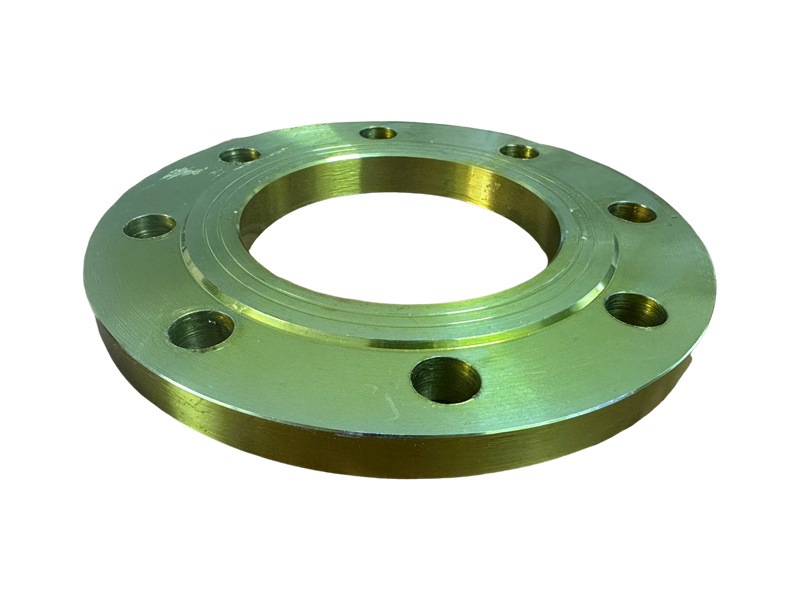

Top Applications of GOST Slip-On Flanges in Architecture The world of architecture is constantly evolving, with materials and techniques that enhance both functionality and aesthetics. One of the essential components in modern construction is the **GOST Slip-On Flange**, a type of fitting that plays a crucial role in connecting pipes and enhancing structural integrity. This article explores the **

Contact information

Address: North Ring Industrial Zone, Mengcun County

Telephone: 86 0317- 6729218 86 0317-6727320

Fax: 0317-6727310

mobile phone: 86 13833761688whatsapp: 86-13780271039

Email: shengyuanflange@163.comLeave Message